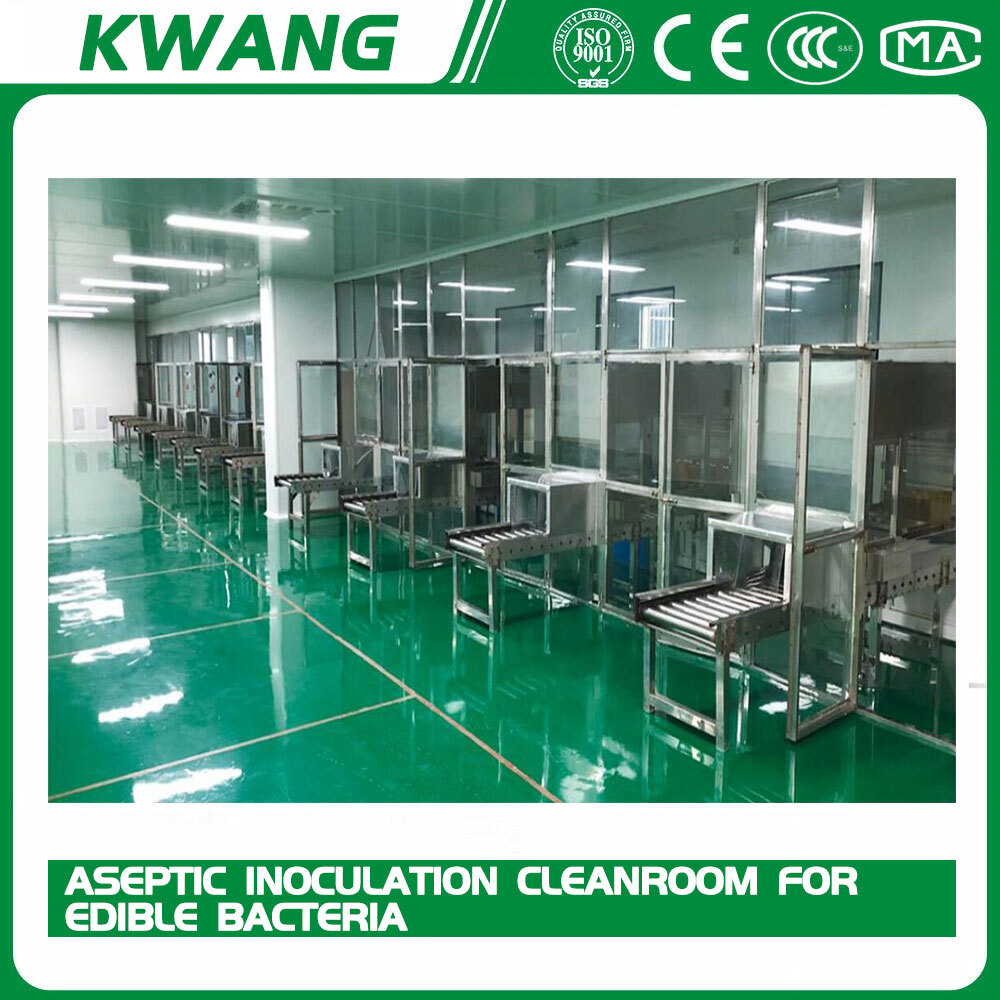

Aseptic inoculation Cleanroom For Edible Bacteria

A number of basic procedures must be followed when handling sterile equipment or working in a sterile environment. These include: ensuring that the environment is free from external sources of contamination, such as open windows or doorways and ensuring that any tools or implements to be used have been thoroughly sterilized. In addition, all sterilized equipment should be easy to reach to prevent the likelihood of having to touch or lean on the surface.

What advanced aseptic techniques are employed in microbiology?

Research and industrial laboratories working with highly sensitive, dangerous, or expensive microorganisms utilize a variety of additional paraphernalia to ensure that sterile conditions are maintained.

Laminar flow hoods or cabinets that keep a constant flow of air across a work surface ensure that no airborne contaminants will enter the space. Where required, larger spaces known as cleanrooms may be used that maintain laminar or turbulent air flow throughout the whole room.

Finally, workers are usually required to use specialised furniture and clothing in these spaces to prevent the introduction of contaminants or infection by microorganisms being worked with.

After bagging, the bacteria packets enter the high temperature sterilization cabinet for sterilization treatment. After coming out of the cabinet, they enter the 300,000-grade pre-cooling room. After pre-cooling, they enter the 100,000-grade strong cooling room for cooling treatment, and then enter the 10,000-grade asepsis room.

The assembly line inoculation workbench provides the FEDERAL standard 209E grade 100 inoculation environment. Through efficient inoculation on the assembly line, the sterile and dust-free inoculation environment is achieved, so as to provide a high standard sterile environment for the survival rate of inoculation. The production line inoculating platform of Yichun company obtained CE certification quality assurance.

Flow of people process: divided into shoe change, one more two more, hand washing, disinfection, wind shower, into the inoculation room.

Logistics process: after packing, enter post-high temperature sterilization cabinet, 300,000-grade pre-cooling room, 100,000-grade strong cooling room, 10,000-grade aseptic inoculation room and 100-grade aseptic inoculation table for aseptic inoculation.

Constant temperature and humidity engineering includes: constant temperature and humidity workshop, constant temperature and humidity warehouse, constant temperature and humidity laboratory, etc. Limit and control temperature, humidity, cleanliness range and control precision, so that the system temperature and humidity in any room or to be determined space in balance.

Microorganisms may be present in the cleanroom, but they are not pathogenic. This is a standard that won’t duplicate bacteria or create more viruses. Aseptic processes require an understanding of the existing microorganisms, and knowing which will compromise the product. Microorganisms that will contaminate the product are excluded. Aseptic processing facilities include easily cleanable floors, walls and ceilings of smooth hard surfaces, temperature and humidity controls, and HEPA filters to filter the air supply into the cleanroom. Aseptic processes also include procedures for using sterile instruments and gloves.

Aseptic and sterile processes work hand in hand to create a stable cleanroom environment, prevent contamination and protect the integrity of your product. Regulations for cleanroom design are intended to make these processes sustainable. When a cleanroom is compromised due to contamination, the result is a time-consuming and expensive shutdown, cleaning and re-certification. Contamination can also hurt your brand’s reputation and financial bottom line. To avoid these harmful ramifications, it is important execute a comprehensive training program for personnel and keep up with cleanroom maintenance and certifications.

As a cleanroom performance testing contractor, Sure-BioChem Laboratories has experience and expertise in a variety of cleanroom processes and applications. Our breadth of knowledge on sterilisation and aseptic processes make us a preferred source for cleanroom certification in accordance with ISO specifications. Our team provides testing and monitoring for HEPA air filter integrity, room pressurisation, temperature and humidity monitoring and environmental monitoring of air and surface microbes. In addition, we can provide your personnel with competency training for cleanroom best practices and aseptic technique.