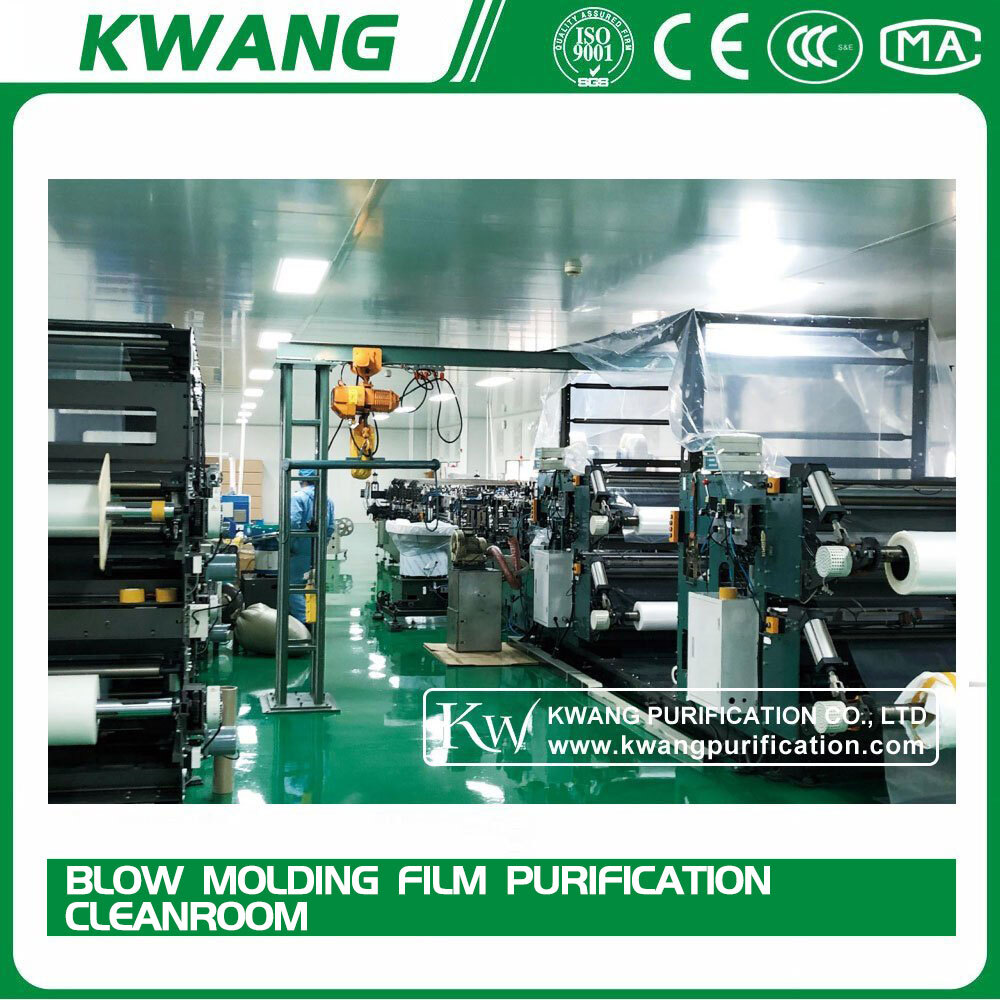

Blow Molding Film Purification Cleanroom

Purification control of blow film workshop, Control the clean environment of production from the centralized material supply source to the dust-free sterile design of blowing film and spraying film, to ensure that each environmental material is always in a clean and dust-free space, so as to ensure that the final product meets the requirements of asepsis. Professional process design is the premise of ensuring qualified products. All personnel entry and exit need to go through every link of shoe change, clothing change, hand washing disinfection control, precise control, step by step control from the control process, so as to ensure the final result.

Clean area: 4200m² (sqm)

Project Introduction:

Participate in the whole process of plant design and construction, arrange and design the production equipment of the needs of water, electricity, gas and other future supporting equipment and pipeline in the early stage, so as to ensure fast and accurate cooperation in the later installation process of clean plant. In order to shorten the construction period and waste of resources caused by repeated transformation, we should make design plans in advance with professional perspective and professional design.

Plastic film purification plant includes blow molding, injection molding, blister molding, extrusion, film and other plastic molding industries. Such workshops in addition to achieving dust-free, but also workshop to maintain a good working environment, while the odor treatment, exhaust gas emissions to deal with environmental protection and other issues.

Purification workshop is purification plant wall, top plate is generally more than 50mm thick sandwich color steel plate manufacturing, its characteristics are beautiful, rigid, good insulation performance, easy construction. Rounded corners, doors, window frames and other general use of special aluminum oxide profiles manufactured ground can be used epoxy self-flow flooring or senior wear-resistant plastic flooring, anti-static requirements, anti-static type can be used. Supply and return air ducts made of hot duct zinc plate, paste purification and good insulation effect of flame retardant PF foam plastic plate efficient air outlet with stainless steel frame, beautiful and clean, perforated mesh plate with baking paint aluminum plate.