Cleanroom Manufacturer: Crafting Controlled Environments for Precision

- 2024-01-22

- View 9

Cleanrooms are pivotal in today's manufacturing landscape, where the demand for utmost precision and sterility is non-negotiable. These controlled environments find applications across various industries, from pharmaceuticals and electronics to biotechnology and aerospace. At the heart of every efficient cleanroom lies the expertise of a cleanroom manufacturer. In this article, we'll explore the vital role of cleanroom manufacturers their contributions, and how they craft these specialized environments to meet the stringent standards of modern industries.

Introduction

Cleanrooms are specialized environments designed to maintain extremely low levels of particulate contamination and ensure precise control over environmental factors such as temperature, humidity, and pressure. They are vital in industries where product quality and safety are paramount.

Cleanroom Essentials

2.1. Why Cleanrooms Matter

Cleanrooms are essential because they protect products and processes from contamination, ensuring that they meet the strictest quality and safety standards.

2.2. The Role of Cleanroom Manufacturers

Cleanroom manufacturers play a pivotal role in crafting these controlled environments. They bring expertise, technology, and innovation to design, build, and maintain cleanrooms tailored to the specific needs of their clients.

Designing a Cleanroom

3.1. Customization and Tailoring

Cleanroom manufacturers understand that one size does not fit all. They customize cleanroom designs to meet the unique requirements of each client, taking into account factors like cleanliness level, space constraints, and budget.

Cleanrooms are classified based on the number of particles allowed per cubic meter. Manufacturers ensure that cleanrooms meet the desired classification, whether ISO 1 (the cleanest) or ISO 9 (the least clean).

Key Components and Materials

4.1. Air Filtration Systems

Air filtration is at the core of cleanroom design. Manufacturers integrate high-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters to remove airborne particles effectively.

4.2. Wall and Ceiling Materials

Cleanroom walls and ceilings are constructed with materials that are easy to clean and maintain, while also preventing the shedding of particles. Common materials include stainless steel and high-pressure laminates.

Safety and Compliance

5.1. Safety Protocols

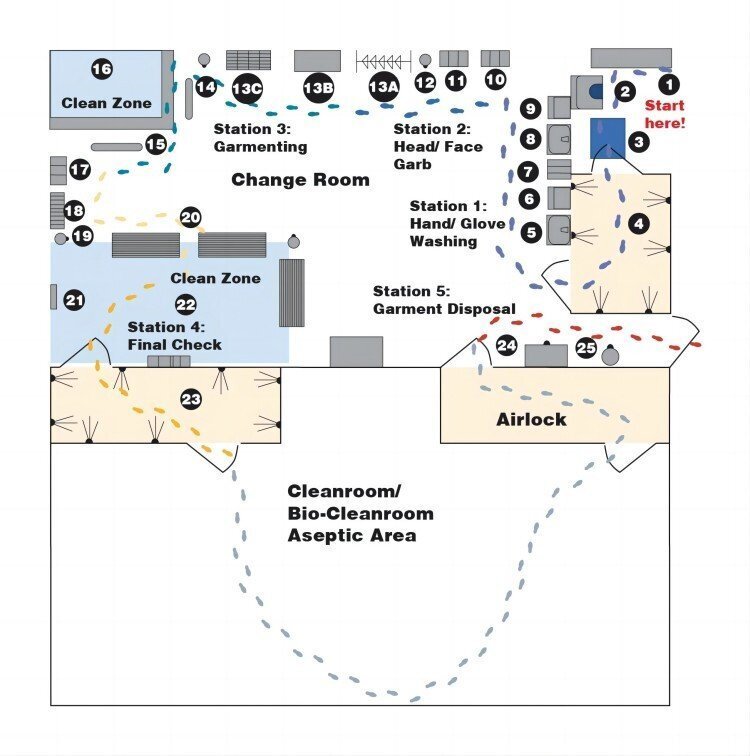

Manufacturers prioritize safety within cleanrooms, implementing protocols such as gowning procedures, training, and emergency response plans to protect personnel and products.

5.2. Regulatory Compliance

Cleanroom manufacturers ensure that their designs and installations comply with industry-specific regulations, such as FDA guidelines for pharmaceutical cleanrooms or ISO standards for semiconductor cleanrooms.

Applications Across Industries

6.1. Pharmaceutical and Biotech Cleanrooms

Pharmaceutical and biotechnology industries rely on cleanrooms to produce drugs, vaccines, and biologics in sterile and controlled environments, preventing contamination that could jeopardize public health.

6.2. Electronics and Semiconductor Cleanrooms

In electronics manufacturing, cleanrooms are critical for producing microchips and semiconductors, where even a tiny particle can disrupt functionality. Cleanroom manufacturers tailor solutions to meet the exacting demands of this industry.

Future Trends and Innovations

7.1. Cleanroom Automation

Automation is on the horizon, with cleanroom manufacturers exploring robotic systems for tasks like cleaning and maintenance, further reducing human contamination risks.

7.2. Sustainable Cleanroom Solutions

Manufacturers are increasingly focusing on sustainable practices, incorporating energy-efficient systems and materials to reduce the environmental impact of cleanrooms.

Conclusion

Cleanroom manufacturers are the architects behind the scenes, crafting controlled environments that are vital to industries requiring precision, cleanliness, and compliance. As technology advances and industries evolve, the role of cleanroom manufacturers remains integral.

FAQs

How long does it take to build a custom cleanroom?

The timeline for building a custom cleanroom varies based on size, complexity, and client requirements, but it typically ranges from a few weeks to several months.

What is the difference between a cleanroom and a controlled environment?

A cleanroom is a type of controlled environment, specifically designed to minimize particulate contamination. Controlled environments encompass a broader range of settings with varying levels of control.

Do cleanrooms require continuous monitoring?

Yes, cleanrooms require continuous monitoring of environmental parameters, including particle counts, temperature, humidity, and pressure, to ensure they remain within specified limits.

Can cleanrooms be expanded or modified after initial construction?

Cleanrooms are designed with flexibility in mind, allowing for expansion or modification as the needs of the facility evolve.

What is the cost range for building a cleanroom?

The cost of building a cleanroom can vary widely based on size, complexity, and customization. Small cleanrooms may start at a few thousand dollars, while large, highly specialized cleanrooms can cost millions.

For inquiries about cleanroom solutions tailored to your specific needs, contact a reputable cleanroom manufacturer in your area. These experts can provide guidance and expertise to create the ideal controlled environment for your industry.