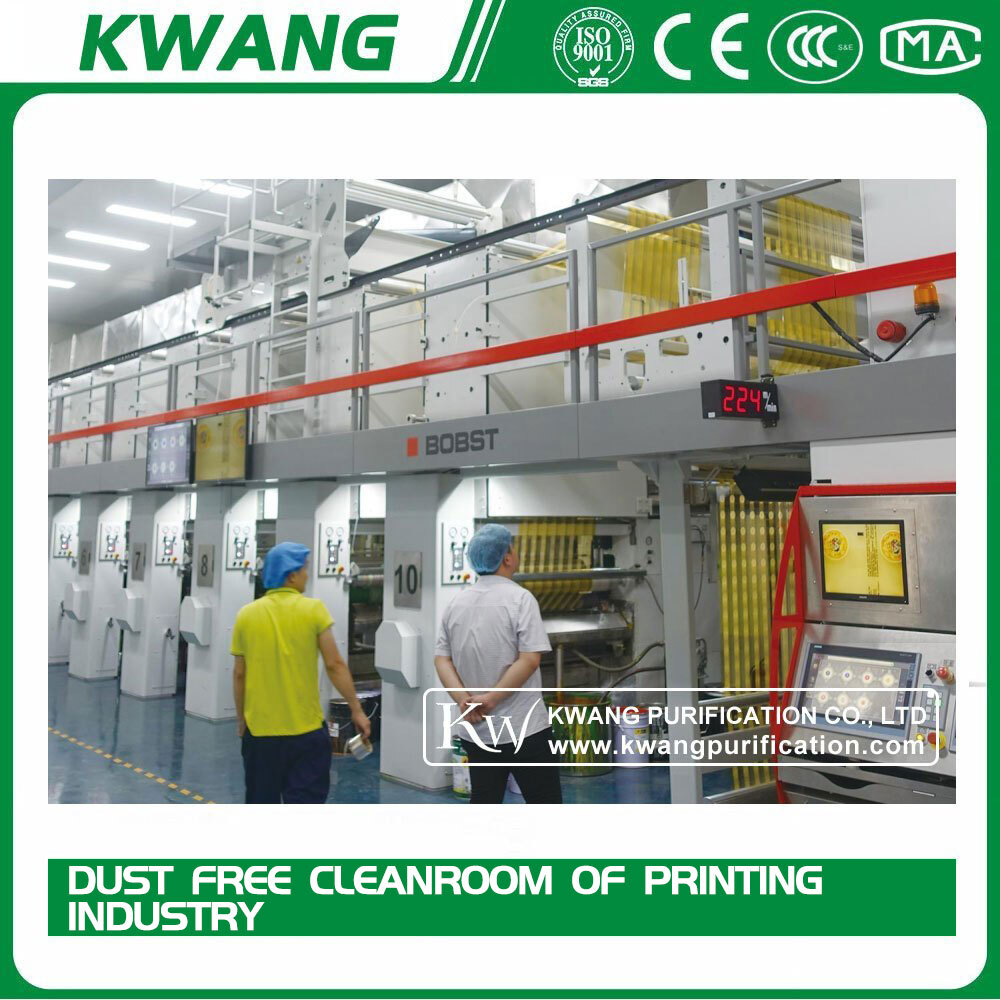

Dust Free Cleanroom Of Printing Industry

Cleanrooms are essential to any manufacturing process where particulate contamination can affect the quality of goods produced. They provide secure environments with controlled air filtration, lowering the possibility of product contamination or large particulate interference with critical process manufacturing.

Dust Free Cleanroom Of Printing Industry are often used in screen printing and digital printing facilities to prevent contamination and dust particles from getting into inks, adhesives, and assemblies. They are also used in critical assembly processes to ensure higher quality parts and lower reject rates.

Dust Free Cleanroom Of Printing Industry create classified environments to protect processes from harmful airborne contamination, thereby reducing failure rates. At Kwang Cleanroom, we offer an economical approach to your printing cleanroom needs and strive to supply cost-effective products without compromising on quality.

Clean area: 9000m² (sqm)

Project Introduction:

From the beginning of the film blowing process to the layout of printing equipment, equipment of exhaust design, to the dry type composite link, and then to curing curing, cutting process, finally to bag molding workshop, considered whether it will be accurate control, ensure the clean sterile control each link, will lead to better control of the finished product of sterile.

In printing, a small particle of dust on material prior to laying down ink can look substantial after the ink adheres and dries around it. In particular, tinted windows on overlays or membrane switches and wet-out windows (WOW) are susceptible to contamination from dirt and dust. A wet-out window (WOW) is a window where clear ink is used to clarify the hard-coated texture on a material to level out the textured peaks and valleys of a surface.

This is used when the material covers LED, LCD, or other displays. Without cleanrooms, the contamination caused by dirt particles, lubricant particles, aerosols or small water droplets would lead to a lower quality finished product.

Pad printing is a fast, quick-drying process allowing for adjustment to ink coverage, density and evaporation. However, it is vulnerable to the changing conditions in the environment surrounding the printing area. Because of this, it is necessary to set up a cleanroom to protect these jobs from exposure to any variables and contaminants that could impact the quality of the finished product.

Even though cleanrooms are not necessary for printing and assembly, they are critical for improving quality, controlling the environment to better process inks, reducing scrap and thus allowing the manufacturer to reduce expenses and pass along savings to the end customer.

There are three things that keep a Cleanroom clean, control and quality of the air, internal surfaces and equipment and standard operating procedures for workers.

A secure environment will have a cleanliness level that is quantified by the number of particles for every cubic metre at a fixed molecule measure. Typically, printing Cleanrooms are designed with positive pressure to force air out and specialised filtration to reduce particulates in incoming air. The lower the quantity and smaller the size of particulates in the room (as measured by volume), the cleaner the room.

We make use of both a complex control system and an independent monitoring system which enable the continuous monitoring of air pressure, temperature, humidity and the number of viable and non-viable particles in the air. We also install temperature and humidity sensors and particle sensors in the modular printing Cleanrooms.

At Kwang Cleanroom, our team manufactures technology that counts the number of particles in the air, and then calculates their results accordingly. By so doing, we measure the cleanliness levels of the printing Cleanroom and controlled environments for sensitivity and contamination analysis.

We provide modular printing Cleanrooms that are impervious to liquids and chemicals, are resistant to impact, minimise the level of airborne particles, facilitate easy clean-up of bio-hazardous material and mitigate the potential for bacterial growth.