Exploring the Significance of Class 100 Clean Rooms in High-Tech Industries

- 2024-01-16

- View 9

In the world of manufacturing and technology, precision and cleanliness are of paramount importance. This is where clean room Class 100 comes into play. In this article, we will delve into the intricacies of clean rooms specifically focusing on Class 100 clean rooms. From their definition to their applications and maintenance, we've got you covered.

What Is a Clean Room?

Clean rooms are controlled environments designed to minimize contamination and maintain specific levels of cleanliness. They find applications in various industries, including semiconductor manufacturing, pharmaceuticals, biotechnology, and aerospace Clean rooms are classified based on their level of cleanliness, with Class 100 being one of the most stringent categories.

Class 100 Clean Room: The Basics

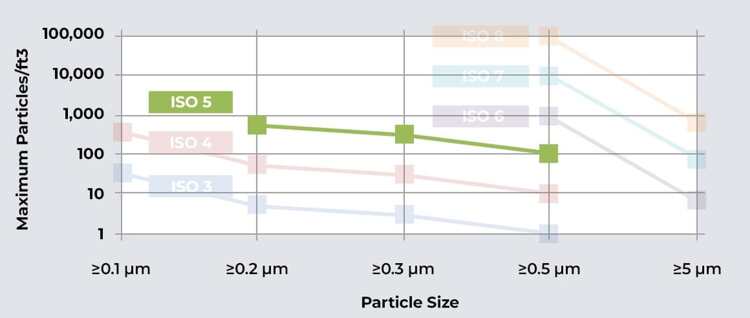

A Class 100 clean room, also known as ISO 5, is a controlled environment where the concentration of airborne particles is limited to 100 particles per cubic foot (approximately 3,520 particles per cubic meter). Achieving and maintaining this level of cleanliness is crucial for industries where even the tiniest particle can lead to product defects or compromise research results.

Why Class 100 Clean Rooms Are Essential

Microelectronics Manufacturing

In the microelectronics industry, such as semiconductor manufacturing, the tiniest speck of dust or particle can lead to the failure of electronic components. Class 100 clean rooms are essential for ensuring the reliability and performance of these sensitive devices.

Pharmaceutical and Biotechnology

In pharmaceutical and biotechnology research, maintaining a sterile environment is critical. Class 100 clean rooms are used for the production of sterile drugs, medical devices, and conducting research on sensitive biological materials.

Aerospace and Optics

Aerospace and optics industries require precision manufacturing. Class 100 clean rooms play a vital role in ensuring the quality of optical components, spacecraft components, and other high-tech equipment.

Building and Maintaining Class 100 Clean Rooms

Design and Construction

Building a Class 100 clean room involves meticulous planning and construction. Walls, floors, and ceilings are constructed with materials that minimize particle generation. High-efficiency particulate air (HEPA) filters and air handling systems are installed to maintain cleanliness levels.

HVAC Systems

The HVAC (Heating, Ventilation, and Air Conditioning) system is the heart of a clean room. It continuously filters and circulates air, removing contaminants. Regular maintenance and filter replacement are imperative to ensure optimal performance.

Clean Room Protocol and Safety

Dress Code

Anyone entering a Class 100 clean room must adhere to a strict dress code. This typically includes wearing cleanroom garments, gloves, and sometimes even face masks or hoods to prevent particle shedding from the body.

Access Control

Access to clean rooms is controlled, and entry is restricted to authorized personnel only. This helps in minimizing the risk of contamination from outside sources.

Conclusion

In conclusion, Class 100 clean rooms are vital for industries that demand an ultra-clean and controlled environment. From microelectronics to pharmaceuticals and aerospace, their applications are diverse and crucial. Building and maintaining these clean rooms require meticulous planning and adherence to stringent protocols.

For more information on clean room Class 100 and how it can benefit your industry, feel free to access now.

FAQs

1. What is the main purpose of a Class 100 clean room?

Class 100 clean rooms are designed to maintain a controlled environment with a limited concentration of airborne particles, ensuring product quality and research integrity.

2. How often should HVAC filters be replaced in a Class 100 clean room?

HVAC filters should be replaced regularly, typically every three to six months, to maintain optimal air quality.

3. Are Class 100 clean rooms only used in manufacturing?

No, Class 100 clean rooms find applications in various industries, including pharmaceuticals, biotechnology, and aerospace, where cleanliness and precision are essential.

4. What is the significance of the ISO 5 classification for clean rooms?

ISO 5 is equivalent to Class 100, indicating that there are no more than 100 particles per cubic foot in the air, making it suitable for highly sensitive applications.

5. How can I ensure the long-term performance of a Class 100 clean room?

Regular maintenance, strict adherence to clean room protocols, and a well-maintained HVAC system are key to ensuring the long-term performance of a Class 100 clean room.