Understanding ISO 5 Clean Rooms: A Comprehensive Guide

- 2024-05-23

- View 12

In today's ever-evolving technological landscape, cleanliness and precision are of utmost importance in various industries such as pharmaceuticals, electronics, and aerospace. The term "ISO 5 clean room" may sound unfamiliar to many, but it plays a critical role in maintaining the highest standards of cleanliness and contamination control. In this article, we will delve deep into ISO 5 clean rooms exploring what they are, their significance, and their applications. So, let's embark on this journey to discover the world of ISO 5 clean rooms.

Introduction to ISO 5 Clean Rooms

Clean rooms are controlled environments where the level of airborne particles, such as dust, microbes, and aerosol particles, is meticulously regulated to prevent contamination. ISO 5 clean rooms are the epitome of cleanliness, designed to maintain an environment with no more than 3,520 particles per cubic meter that are larger than 0.5 micrometers in size.

The Importance of Clean Rooms

Clean rooms are indispensable in industries where even the tiniest particle can have catastrophic consequences. They ensure product quality, safeguard research integrity, and protect the health and safety of individuals.

ISO Classifications: What Sets ISO 5 Apart?

3.1. ISO 1 to ISO 9: A Brief Overview

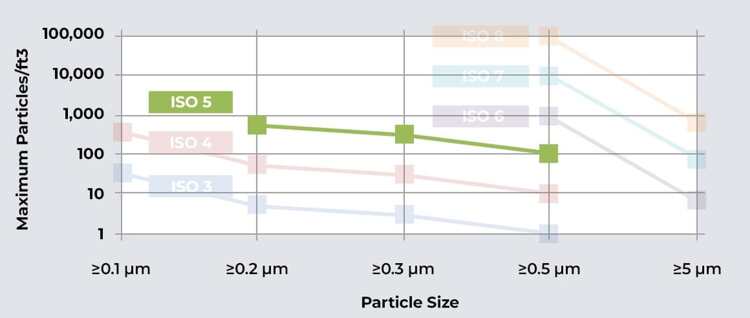

Before diving into ISO 5, let's briefly explore the entire ISO classification system, which spans from ISO 1 (the cleanest) to ISO 9 (the least clean). Each class has its specific particle count limits, with ISO 1 being the most stringent.

3.2. Defining ISO 5 Clean Rooms

ISO 5 clean rooms are known for their exceptional cleanliness, allowing a minimal number of particles. They are designed to meet the highest standards, making them suitable for critical industries like pharmaceuticals and electronics.

Designing an ISO 5 Clean Room

Creating an ISO 5 clean room involves meticulous planning and execution. The design must consider various factors and materials to maintain the required cleanliness.

4.1. Controlled Environment Factors

Temperature, humidity, and pressure are tightly controlled to create a stable environment that minimizes particle movement.

4.2. Materials and Surfaces

The choice of materials and surfaces must be compatible with the stringent cleanliness requirements, ensuring easy cleaning and minimal particle shedding.

Air Quality and Filtration

Clean air is the backbone of ISO 5 clean rooms, achieved through high-efficiency particulate air (HEPA) filters and precise airflow control.

5.1 HEPA Filters: The Heart of Clean Rooms

HEPA filters remove particles down to 0.3 micrometers in size, making them indispensable in maintaining ISO 5 standards.

5.2. Airflow Control

Proper airflow direction and velocity ensure that particles are constantly removed from the clean room environment.

Maintenance and Monitoring

Sustaining ISO 5 cleanliness requires consistent maintenance and monitoring procedures.

6.1. Regular Inspections and Cleaning

Frequent inspections and thorough cleaning routines are vital to prevent contamination.

6.2. Particle Counting and Contamination Control

Advanced particle counting techniques are employed to monitor and control particle levels within the clean room.

Applications of ISO 5 Clean Rooms

ISO 5 clean rooms find applications in several industries where precision and cleanliness are non-negotiable.

7.1. Pharmaceutical Industry

Pharmaceutical companies rely on ISO 5 clean rooms to manufacture drugs without the risk of contamination.

7.2. Electronics Manufacturing

The electronics industry benefits from ISO 5 clean rooms to assemble sensitive components in a dust-free environment.

7.3. Biotechnology and Medical Device Production

Biotech firms and medical device manufacturers utilize ISO 5 clean rooms for research and production.

Challenges in Maintaining ISO 5 Standards

Despite their critical role, ISO 5 clean rooms pose significant challenges, including high operational costs and the need for rigorous training and adherence to protocols.

Conclusion

ISO 5 clean rooms are the pinnacle of cleanliness in controlled environments, playing a crucial role in ensuring product quality and safety in various industries. Maintaining these standards demands unwavering dedication and precision, but the benefits far outweigh the challenges.

FAQs

What distinguishes ISO 5 clean rooms from other ISO classifications?

ISO 5 clean rooms maintain the strictest particle count limits, allowing no more than 3,520 particles larger than 0.5 micrometers per cubic meter.

How are ISO 5 clean rooms used in the pharmaceutical industry?

Pharmaceutical companies utilize ISO 5 clean rooms for drug manufacturing to prevent contamination and ensure product purity.

What role do HEPA filters play in ISO 5 clean rooms?

HEPA filters are essential for removing particles down to 0.3 micrometers in size, ensuring clean air within the clean room.

What are the challenges of maintaining ISO 5 clean rooms?

Challenges include high operational costs, stringent protocols, and the need for continuous training and monitoring.

Where can I learn more about ISO 5 clean rooms?

For further information on ISO 5 clean rooms and their applications, access our comprehensive guide.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Cleanroom ISO Class Standards, ISO 4 Clean Room, ISO Class 5 Cleanroom, ISO Class 6 Cleanroom, ISO Class 7 Cleanroom, ISO Class 8 Cleanroom, ISO Clean Room.