Decontamination Room: Design Principles, Equipment, and Process

- 2024-05-01

- View 13

As the world is facing unprecedented public health challenges decontamination rooms have become a critical feature in many industries. Whether you are operating in the healthcare sector, food processing, or manufacturing, it is essential to have a well-designed decontamination room that can prevent the spread of harmful microorganisms. In this article, we will explore the design principles and functionality of decontamination rooms and provide you with actionable tips to set up your own.

What is a decontamination room?

A decontamination room is a specialized area that is designed to eliminate or reduce the number of harmful microorganisms, chemicals, or other contaminants from personnel and equipment before they enter or leave a controlled environment The purpose of a decontamination room is to prevent the spread of pathogens or hazardous substances and ensure that the working environment remains safe and clean.

The Importance of Decontamination Rooms

Decontamination rooms play a crucial role in preventing the spread of infectious diseases, bacteria, and viruses, such as COVID-19, Ebola, and other highly contagious diseases. These rooms are designed to minimize the risk of contamination by providing a controlled environment where personnel can undergo thorough decontamination procedures. A decontamination room is also an essential feature in many industrial applications, including the pharmaceutical industry, food processing, and electronics manufacturing.

Design Principles of a Decontamination Room

1. Segregated Entrance and Exit

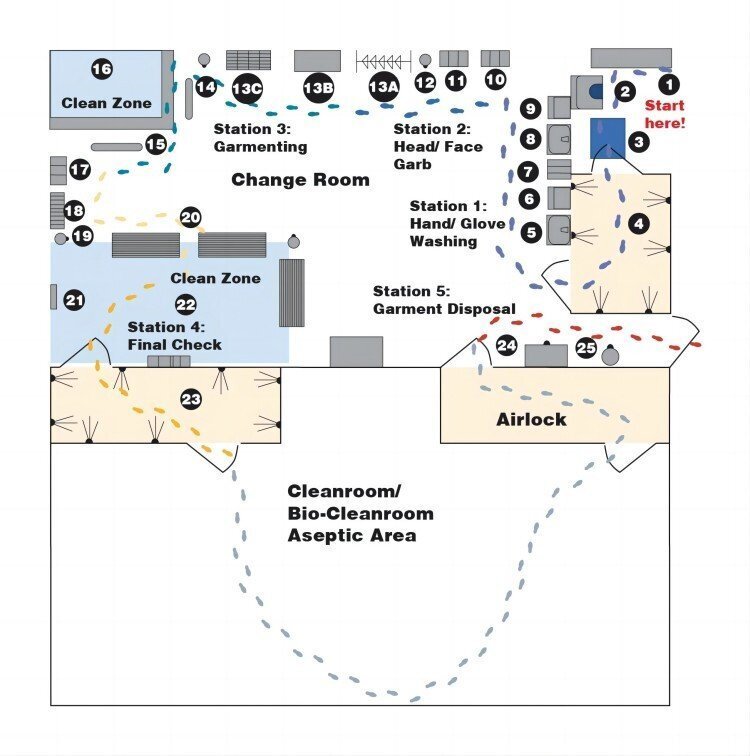

The first design principle of a decontamination room is to have a segregated entrance and exit. This ensures that personnel and equipment enter and leave the decontamination room through separate entrances, minimizing the risk of cross-contamination.

2. Airlocks

An airlock is an essential feature of a decontamination room that is designed to prevent the escape of contaminated air. The airlock typically consists of two doors, and personnel must undergo a decontamination procedure before entering or leaving the room.

3. Negative Pressure Room

A negative pressure room is a specialized room that is designed to prevent airborne pathogens or hazardous substances from escaping the room. The negative pressure in the room ensures that contaminated air is continually drawn into the room and filtered out before it is exhausted outside.

4. Controlled Ventilation

A decontamination room should have controlled ventilation to ensure that the room's air is continually replaced with clean, filtered air. The ventilation system should have high-efficiency particulate air (HEPA) filters that can trap even the smallest particles.

5. Stainless Steel Construction

Decontamination rooms should be constructed from stainless steel, which is easy to clean and does not harbor bacteria or other harmful microorganisms. Stainless steel is also resistant to corrosion and can withstand harsh cleaning chemicals.

6. Personal Protective Equipment

Personnel must wear personal protective equipment (PPE) when entering a decontamination room. The PPE includes gloves, masks, gowns, and footwear, which must be removed and disposed of appropriately after the decontamination procedure.

The Decontamination Process

The decontamination process is a critical aspect of a decontamination room's functionality. The decontamination process typically involves several stages, including:

1. Initial Cleaning

The initial cleaning stage involves the removal of any visible debris, dirt, or other contaminants from personnel or equipment.

2. Pre-Rinse

The pre-rinse stage involves rinsing personnel or equipment with clean, filtered water to remove any loose particles.

3. Soap Application

The soap application stage involves applying a cleaning agent or soap to personnel or equipment to remove any remaining contaminants.

4. Scrubbing

The scrubbing stage involves manually scrubbing personnel or equipment to ensure that all visible dirt, grime, and contaminants are removed.

5. Final Rinse

The final rinse stage involves rinsing personnel or equipment with clean, filtered water to remove any remaining soap or cleaning agents.

6. Disinfection

The disinfection stage involves applying a disinfectant solution to personnel or equipment to kill any remaining bacteria or viruses.

7. Final Rinse and Drying

The final rinse and drying stage involve rinsing personnel or equipment with clean, filtered water and allowing them to dry completely before leaving the decontamination room.

Tips for Setting Up a Decontamination Room

When setting up a decontamination room, it is essential to follow some practical tips to ensure that the room is safe, efficient, and functional. Here are some tips for setting up a decontamination room:

1. Choose the Right Location

The location of the decontamination room should be separate from other work areas to minimize the risk of contamination. The room should also be located near an external door for easy access.

2. Design the Room Layout Carefully

The layout of the decontamination room should be carefully designed to ensure that personnel and equipment move through the room efficiently. The room should also be easy to clean and maintain.

3. Choose the Right Equipment

The equipment used in the decontamination room should be of high quality and designed for the specific application. For example, the ventilation system should have HEPA filters, and the disinfectant solution should be appropriate for the type of contaminants being treated.

4. Train Personnel

Personnel working in the decontamination room should be trained on the proper use of equipment, decontamination procedures, and PPE. Regular training sessions should also be held to ensure that personnel are up-to-date with the latest procedures and protocols.

Conclusion

In conclusion, a decontamination room is a critical feature in many industries, and its design and functionality should be carefully considered to ensure that it is safe, efficient, and effective in preventing the spread of harmful microorganisms. By following the design principles and tips outlined in this article, you can set up your own decontamination room and help protect your personnel and equipment from contamination.

FAQs

What is the purpose of a decontamination room?

The purpose of a decontamination room is to prevent the spread of pathogens or hazardous substances and ensure that the working environment remains safe and clean.

What are the design principles of a decontamination room?

The design principles of a decontamination room include a segregated entrance and exit, airlocks, negative pressure room, controlled ventilation, stainless steel construction, and personal protective equipment.

What is the decontamination process?

The decontamination process typically involves several stages, including initial cleaning, pre-rinse, soap application, scrubbing, disinfection, final rinse, and drying.

What are the tips for setting up a decontamination room?

Some tips for setting up a decontamination room include choosing the right location, designing the room layout carefully, choosing the right equipment, and training personnel.

Why is a decontamination room important?

A decontamination room is important because it helps prevent the spread of infectious diseases, bacteria, and viruses, such as COVID-19, Ebola, and other highly contagious diseases.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Aseptic Purification Cleanroom Of Food Factory、 Electronic Dust Free Cleanroom、 GMP Cleanroom For Medical Devices、 Dust Free Cleanroom Of Printing Industry、 Blow Molding Film Purification Cleanroom、 Aseptic inoculation Cleanroom For Edible Bacteria、 Purification Projects In Other Industries.