ISO Cleanroom Classifications: Understanding the Basics

- 2024-01-31

- View 13

Cleanrooms are critical environments that must maintain strict control over airborne contaminants to ensure the safety and efficacy of products manufactured within them. ISO cleanroom classifications provide a standardized system for classifying cleanroom environments based on the maximum number of airborne particles allowed per cubic meter of air. In this article, we'll explore the basics of ISO cleanroom classifications and how they are used to ensure the quality and safety of products produced within these critical environments.

Table of Contents

What are cleanrooms?

Why are cleanrooms important?

What are ISO cleanroom classifications?

How are ISO cleanroom classifications determined?

ISO cleanroom classifications: ISO 1-9

ISO 1 cleanroom

ISO 2 cleanroom

ISO 3 cleanroom

ISO 4 cleanroom

ISO 5 cleanroom

ISO 6 cleanroom

ISO 7 cleanroom

ISO 8 cleanroom

ISO 9 cleanroom

Maintaining ISO cleanroom standards

Cleanroom equipment and supplies

Cleanroom clothing and personal protective equipment

Cleanroom cleaning and maintenance

Common applications of cleanrooms

Challenges and limitations of cleanrooms

Conclusion

FAQs

1. What are cleanrooms?

A cleanroom is a controlled environment that is designed to minimize the presence of airborne particles and other contaminants. These environments are used in a variety of industries, including pharmaceuticals, biotechnology, electronics manufacturing, and aerospace. Cleanrooms can range in size from small chambers to large manufacturing facilities and can be designed to meet specific requirements based on the needs of the industry.

2. Why are cleanrooms important?

Cleanrooms are essential for industries that require a controlled environment to produce products that are safe and effective. Airborne contaminants can impact the quality and safety of products, leading to recalls, contamination, and other issues that can be costly and dangerous. By maintaining strict control over the environment, cleanrooms can help ensure that products are produced to the highest standards and are safe for consumers to use.

3. What are ISO cleanroom classifications?

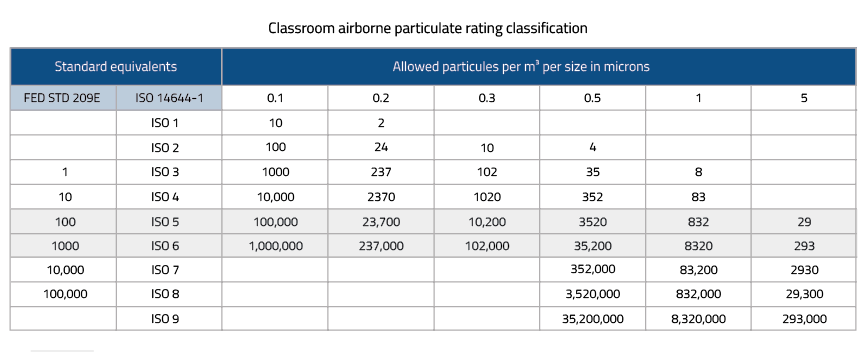

ISO cleanroom classifications are a standardized system for classifying cleanroom environments based on the maximum number of airborne particles allowed per cubic meter of air. These classifications are based on ISO 14644-1, which outlines the requirements for cleanroom environments in terms of airborne particle counts.

4. How are ISO cleanroom classifications determined?

ISO cleanroom classifications are determined based on the maximum number of airborne particles per cubic meter of air, measured at a specified particle size. The particle size used for classification varies depending on the ISO class.

5. ISO cleanroom classifications: ISO 1-9

There are nine ISO cleanroom classifications, ranging from ISO 1 cleanroom to ISO 9 cleanroom, with Class 1 being the most stringent and Class 9 being the least stringent.

ISO 1 cleanroom

ISO 1 cleanrooms are the most stringent classification and must maintain a maximum of 10 particles per cubic meter of air at 0.1 microns or larger.

ISO 2 cleanroom

ISO 2 cleanrooms must maintain a maximum of 100 particles per cubic meter of air at 0.1 microns or larger.

ISO 3 cleanroom

ISO 3 cleanrooms must maintain a maximum of 1,000 particles per cubic meter of air at 0.1 microns or larger.

ISO 4 cleanroom

ISO 4 cleanrooms must maintain a maximum of 10,000 particles per cubic meter of air at 0.1 microns or larger.

ISO 5 cleanroom

ISO 5 cleanrooms must maintain a maximum of 100,000 particles per cubic meter of air at 0.1 microns or larger.

ISO 6 cleanroom

ISO 6 cleanrooms must maintain a maximum of 1,000,000 particles per cubic meter of air at 0.1 microns or larger.

ISO 7 cleanroom

ISO 7 cleanrooms must maintain a maximum of 10,000,000 particles per cubic meter of air at 0.1 microns or larger.

ISO 8 cleanroom

ISO 8 cleanrooms must maintain a maximum of 100,000,000 particles per cubic meter of air at 0.1 microns or larger.

ISO 9 cleanroom

ISO 9 cleanrooms must maintain a maximum of 1,000,000,000 particles per cubic meter of air at 0.1 microns or larger.

6. Maintaining ISO cleanroom standards

Maintaining ISO cleanroom standards requires a comprehensive approach that includes facility design, equipment selection, cleaning and maintenance procedures, and ongoing monitoring and testing. Regular training and education for cleanroom personnel are also essential to ensure compliance with ISO cleanroom standards.

7. Cleanroom equipment and supplies

Cleanroom equipment and supplies must meet strict standards for cleanliness and particle control. Common cleanroom equipment includes laminar flow hoods HEPA filters, and air showers, while cleanroom supplies include gloves, wipes, and garments made from specialized materials designed to minimize particle shedding.

8. Cleanroom clothing and personal protective equipment

Cleanroom clothing and personal protective equipment are critical components of ISO cleanroom standards. Garments worn in cleanrooms must be made from specialized materials that minimize particle shedding, and personnel must wear appropriate personal protective equipment, including gloves, masks, and shoe covers.

9. Cleanroom cleaning and maintenance

Cleanroom cleaning and maintenance procedures are essential for maintaining ISO cleanroom standards. These procedures must be performed regularly and include detailed cleaning of equipment and surfaces, as well as ongoing monitoring and testing to ensure that the environment remains within the appropriate ISO classification.

10. Common applications of cleanrooms

Cleanrooms are used in a wide range of industries and applications, including pharmaceuticals, biotechnology, electronics manufacturing, aerospace, and more. Common applications include the production of sterile medical products, microelectronics, and other high-tech products that require a controlled environment.

11. Challenges and limitations of cleanrooms

While cleanrooms are essential for ensuring the safety and efficacy of products, they can also present challenges and limitations. Maintaining ISO cleanroom standards requires a significant investment of time, resources, and personnel, and cleanrooms can be costly to design, build, and maintain. Additionally, there may be limitations on the size and scope of products that can be produced in cleanroom environments.

12. Conclusion

ISO cleanroom classifications provide a standardized system for classifying cleanroom environments based on the maximum number of airborne particles allowed per cubic meter of air. These classifications are essential for ensuring the safety and efficacy of products produced in cleanroom environments, and maintaining ISO cleanroom standards requires a comprehensive approach that includes facility design, equipment selection, cleaning and maintenance procedures, and ongoing monitoring and testing.

13. FAQs

Why are cleanrooms important?

Cleanrooms are important because they help ensure the safety and efficacy of products produced in controlled environments by minimizing the presence of airborne contaminants.

What are ISO cleanroom classifications?

ISO cleanroom classifications are a standardized system for classifying cleanroom environments based on the maximum number of airborne particles allowed per cubic meter of air.

What are some common applications of cleanrooms?

Cleanrooms are used in a wide range of industries and applications, including pharmaceuticals, biotechnology, electronics manufacturing, and aerospace.

What are some challenges associated with maintaining ISO cleanroom standards?

Maintaining ISO cleanroom standards requires a significant investment of time, resources, and personnel, and cleanrooms can be costly to design, build, and maintain. Additionally, there may be limitations on the size and scope of products that can be produced in cleanroom environments.

What are some common cleanroom equipment and supplies?

Common cleanroom equipment includes laminar flow hoods, HEPA filters, and air showers, while cleanroom supplies include gloves, wipes, and garments made from specialized materials designed to minimize particle shedding.

What is the importance of cleanroom clothing and personal protective equipment?

Cleanroom clothing and personal protective equipment are critical components of ISO cleanroom standards because they help minimize particle shedding and prevent the introduction of contaminants into the cleanroom environment.

What are some key considerations for maintaining ISO cleanroom standards?

Maintaining ISO cleanroom standards requires a comprehensive approach that includes facility design, equipment selection, cleaning and maintenance procedures, ongoing monitoring and testing, and regular training and education for cleanroom personnel.

Where can I learn more about ISO cleanroom classifications?

There are a variety of resources available for learning more about ISO cleanroom classifications, including industry associations, government agencies, and professional organizations.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Modular Cleanroom Systems、 Cleanroom Doors、Cleanroom Windows、Purification Projects In Other Industries.