What is a Class 10000 Clean Room?

- 2024-02-01

- View 15

Cleanrooms are specialized environments designed to limit the level of airborne particles, microorganisms, and other contaminants to provide a controlled, sterile environment for various scientific, medical, and manufacturing processes. A class 10000 cleanroom also known as an ISO 7 cleanroom is a type of controlled environment that meets specific standards regarding the number of particles per cubic meter of air. This article will discuss everything you need to know about class 10000 clean rooms, including their definition, design, applications, and maintenance.

Definition of Class 10000 Clean Room

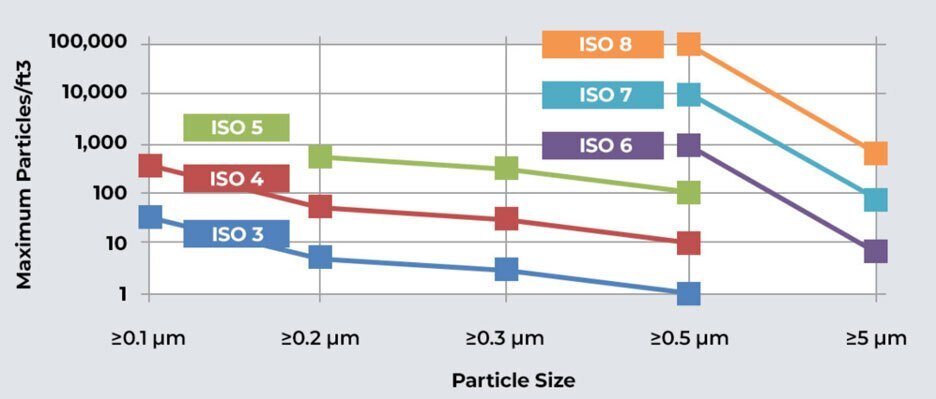

A class 10000 cleanroom is an enclosed, controlled environment that limits the level of airborne particles and microorganisms present in the air. The term "class 10000" refers to the number of particles larger than 0.5 microns per cubic foot of air in the room. In a class 10000 cleanroom, the number of particles larger than 0.5 microns should not exceed 10,000 per cubic foot of air. These cleanrooms are often used in industries that require a controlled environment, including pharmaceuticals, biotechnology, aerospace, and electronics.

Design and Construction of Class 10000 Clean Rooms

Designing a class 10000 cleanroom requires careful planning and attention to detail to ensure the room meets the necessary standards Cleanroom design should consider the layout of the room, HVAC systems, airflow patterns, lighting, and the materials used in construction. The room should be designed to limit the number of potential contaminants, including dust, mold, and bacteria. The walls and ceilings of a cleanroom are typically constructed from non-porous materials, such as stainless steel or plastic, to prevent the growth of microorganisms.

The HVAC system plays a critical role in maintaining a class 10000 cleanroom. The system must be designed to maintain a positive pressure within the room, meaning that the air pressure inside the room is greater than the pressure outside the room. This helps prevent contaminants from entering the cleanroom through small cracks or gaps. The airflow in the room must be carefully controlled to minimize the movement of particles and prevent the buildup of contaminants in certain areas of the room.

Applications of Class 10000 Clean Rooms

Class 10000 clean rooms are used in a variety of industries that require a controlled environment to prevent contamination. One of the most common applications of class 10000 cleanrooms is in the pharmaceutical industry. These rooms are used to manufacture sterile products, such as injectable medications and vaccines, that must meet strict quality standards. Class 10000 clean rooms are also used in the biotechnology industry for cell culture, genetic engineering, and other research applications. Other industries that may use class 10000 cleanrooms include aerospace, electronics, and manufacturing.

Maintenance of Class 10000 Clean Rooms

Maintaining a class 10000 cleanroom requires ongoing attention to ensure the room remains within the necessary standards. The room must be regularly cleaned and disinfected to prevent the buildup of contaminants. The HVAC system must be regularly inspected and maintained to ensure it is functioning correctly. The room should also be monitored regularly to ensure it is meeting the necessary standards for particle count and airflow.

FAQs

1、What is the difference between a class 10000 cleanroom and other classes of cleanrooms?

Class 10000 cleanrooms have a lower number of particles per cubic foot of air compared to other classes of cleanrooms. For example, a class 100 cleanroom has no more than 100 particles larger than 0.5 microns per cubic foot of air, while a class 100000 cleanroom has up to 100,000 particles per cubic foot of air.

2、How do you maintain a class 10000 cleanroom?

To maintain a class 10000 cleanroom, regular cleaning and disinfection are necessary. The HVAC system must also be regularly inspected and maintained to ensure it is functioning correctly. The room should be monitored regularly to ensure it is meeting the necessary standards for particle count and airflow.

3、What industries commonly use class 10000 cleanrooms?

Class 10000 cleanrooms are commonly used in industries that require a controlled environment to prevent contamination, such as pharmaceuticals, biotechnology, aerospace, and electronics.

4、Can a cleanroom be converted into a class 10000 cleanroom?

Yes, it is possible to convert a cleanroom into a class 10000 cleanroom by making modifications to the HVAC system, adding filtration systems, and adjusting the room's layout and construction materials.

5、What is the role of positive pressure in a cleanroom?

Maintaining a positive pressure within a cleanroom helps prevent contaminants from entering the room through small cracks or gaps. Positive pressure means that the air pressure inside the room is greater than the pressure outside the room, creating a barrier against outside contaminants.

Conclusion

Class 10000 clean rooms are a critical component of many industries that require a controlled environment to prevent contamination. These rooms are designed to limit the level of airborne particles and microorganisms present in the air to meet specific standards. Cleanroom design should consider the layout of the room, HVAC systems, airflow patterns, lighting, and the materials used in construction. Regular maintenance and monitoring are necessary to ensure the room remains within the necessary standards.