ISO 7 Class 10,000 Cleanroom Design and Build: Ensuring Controlled Environments

- 2024-01-31

- View 9

Cleanrooms are essential for industries that require controlled environments to ensure the integrity and quality of their processes and products. Among the different classifications of cleanrooms ISO 7 Class 10,000 cleanrooms strike a balance between cleanliness requirements and cost-effectiveness. In this article, we will explore the design considerations, construction process, compliance requirements, and benefits of ISO 7 Class 10,000 cleanrooms.

1. Understanding ISO 7 Class 10,000 Cleanrooms

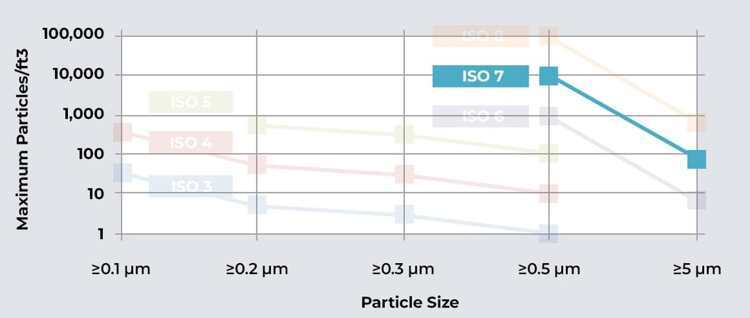

ISO 7 Class 10,000 cleanrooms are designed to limit the concentration of airborne particles larger than 0.5 micrometers to 10,000 particles per cubic foot of air. This classification ensures a controlled environment suitable for industries that need a moderate level of cleanliness, such as pharmaceutical manufacturing, laboratories, and electronics assembly.

2. Design Considerations for ISO 7 Class 10,000 Cleanrooms

Designing an ISO 7 Class 10,000 cleanroom requires careful consideration of various factors to maintain the desired level of cleanliness.

2.1 Air Filtration Systems

Effective air filtration is crucial in ISO 7 Class 10,000 cleanrooms. High-efficiency particulate air (HEPA) filters are commonly used to remove particles from the air, ensuring a low particle count within the cleanroom environment.

2.2 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in ISO 7 Class 10,000 cleanrooms play a vital role in controlling temperature, humidity, and air quality. These systems help maintain stable and optimal conditions for processes and personnel comfort.

2.3 Room Layout and Flow

The layout and flow of an ISO 7 Class 10,000 cleanroom should be designed to minimize cross-contamination and ensure efficient movement of personnel, equipment, and materials. Proper segregation of different processes and the implementation of unidirectional airflow help maintain cleanliness throughout the cleanroom.

3. Construction and Installation

The construction and installation of an ISO 7 Class 10,000 cleanroom require adherence to specific guidelines and industry best practices. Construction materials with low particle generation, such as stainless steel and non-shedding surfaces, are commonly used. The installation of the air filtration and HVAC systems should be carried out meticulously to ensure their effectiveness.

4. Compliance and Certification

To meet regulatory standards and industry requirements, ISO 7 Class 10,000 cleanrooms undergo rigorous testing, validation, and certification processes. Compliance with guidelines such as ISO 14644-1 is essential to ensure the cleanroom consistently meets the specified cleanliness standards.

5. Maintenance and Monitoring

Regular maintenance and monitoring are crucial for the long-term performance and cleanliness of an ISO 7 Class 10,000 cleanroom. Cleaning procedures, filter replacements, and equipment calibrations should be carried out at scheduled intervals to maintain the desired level of cleanliness.

6. Benefits and Applications of ISO 7 Class 10,000 Cleanrooms

ISO 7 Class 10,000 cleanrooms offer several benefits for industries that require controlled environments with a moderate level of cleanliness. Some key benefits include:

Cost-effectiveness compared to higher cleanroom classifications

Adequate cleanliness for various applications such as pharmaceutical manufacturing, laboratories, and electronics assembly

Enhanced product quality and process reliability

Compliance with industry regulations and standards

Improved safety for personnel and products

7. Conclusion

ISO 7 Class 10,000 cleanrooms provide industries with a controlled environment that balances cleanliness requirements and cost-effectiveness. By considering design factors, following proper construction and installation practices, ensuring compliance, and implementing appropriate maintenance procedures, companies can create ISO 7 Class 10,000 cleanrooms that meet their specific needs.

Frequently Asked Questions:

What is an ISO 7 Class 10,000 cleanroom?

An ISO 7 Class 10,000 cleanroom is a controlled environment designed to limit the concentration of airborne particles larger than 0.5 micrometers to 10,000 particles per cubic foot of air. It is suitable for industries that require a moderate level of cleanliness.

What industries can benefit from ISO 7 Class 10,000 cleanrooms?

Industries such as pharmaceutical manufacturing, laboratories, and electronics assembly can benefit from ISO 7 Class 10,000 cleanrooms.

What are the key considerations in designing an ISO 7 Class 10,000 cleanroom?

Key considerations in designing an ISO 7 Class 10,000 cleanroom include air filtration systems, HVAC systems, and room layout to ensure efficient airflow and minimize cross-contamination.

What are the benefits of ISO 7 Class 10,000 cleanrooms?

ISO 7 Class 10,000 cleanrooms offer cost-effectiveness, adequate cleanliness, enhanced product quality, regulatory compliance, and improved safety for personnel and products.

How can ISO 7 Class 10,000 cleanrooms be maintained?

ISO 7 Class 10,000 cleanrooms require regular maintenance, including cleaning procedures, filter replacements, and equipment calibrations, to ensure the desired level of cleanliness is maintained.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Pharmaceutical Purifying Cleanroom, Cleanroom Technician, Cleanroom ISO 6, Class 100 Clean Room, Air Shower Clean Room, Clean Room Factory, Wall Panel Cleanroom.