ISO 1 Clean Room: Maintaining Ultra-Clean Environments for Sensitive Industries

- 2024-02-01

- View 10

Cleanrooms are vital in industries that require a controlled environment to maintain product quality and prevent contamination. An ISO 1 cleanroom is the cleanest classification of cleanrooms, providing an ultra-clean environment for the most sensitive industries. This article will cover the requirements and benefits of ISO 1 cleanrooms, and how they contribute to creating safe and clean work environments.

What is an ISO 1 Clean Room?

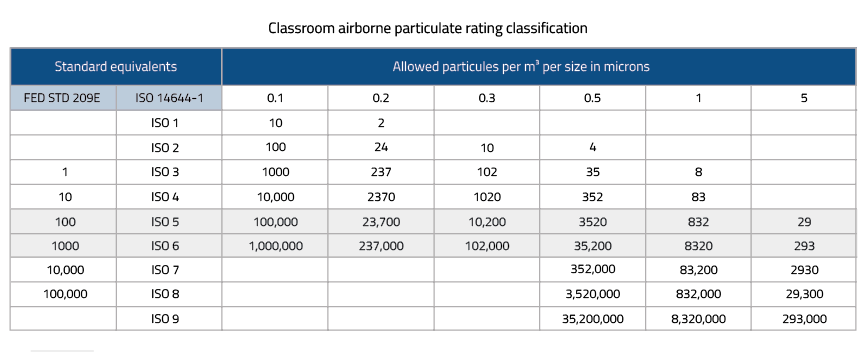

An ISO 1 cleanroom is a controlled environment designed to maintain an ultra-clean environment by limiting airborne particles, such as dust, bacteria, and other microorganisms. ISO 1 cleanrooms have the strictest requirements, allowing only one particle of size 0.1 microns or larger per cubic meter of air.

Requirements for ISO 1 Clean Rooms

To maintain an ISO 1 cleanroom, strict requirements must be met. The following are the essential requirements for ISO 1 clean rooms:

Air Filtration

Air filtration is crucial in an ISO 1 cleanroom. The air must pass through high-efficiency filters, such as HEPA (High-Efficiency Particulate Air) filters, to remove any airborne particles.

Positive Pressure

The cleanroom must maintain positive pressure, meaning that the air pressure inside the room is higher than the surrounding environment. This pressure difference prevents the entry of any unfiltered air from the outside environment.

Gowning and De-gowning Procedures

Proper gowning and de-gowning procedures are critical in maintaining the cleanliness of the ISO 1 cleanroom. Individuals must wear appropriate clothing, including gloves, hoods, and face masks, to prevent the release of any particles.

Airflow Control

The airflow in the cleanroom must be consistent and controlled to prevent any turbulence, which could cause the release of any particles. The direction of the airflow must also be carefully controlled to avoid the cross-contamination of different areas of the cleanroom.

Benefits of ISO 1 Clean Rooms

The benefits of an ISO 1 cleanroom are significant for industries that require a controlled environment. The following are the essential benefits of ISO 1 cleanrooms:

Product Quality

ISO 1 cleanrooms ensure the highest level of product quality by preventing contamination, which is critical in industries such as pharmaceuticals, biotechnology, and electronics.

Health and Safety

ISO 1 cleanrooms provide a safe and healthy work environment by preventing the release of harmful particles, such as bacteria and viruses.

Compliance

Industries that require a controlled environment must comply with strict regulations and guidelines, such as those set by the FDA and ISO. ISO 1 cleanrooms ensure compliance with these regulations and guidelines.

FAQs

Q: What is an ISO 1 cleanroom?

A: An ISO 1 cleanroom is a controlled environment designed to maintain an ultra-clean environment by limiting airborne particles, such as dust, bacteria, and other microorganisms. ISO 1 cleanrooms have the strictest requirements, allowing only one particle of size 0.1 microns or larger per cubic meter of air.

Q: What are the requirements for maintaining an ISO 1 cleanroom?

A: The requirements for maintaining an ISO 1 cleanroom include air filtration, positive pressure, gowning and de-gowning procedures, and airflow control.

Q: Why is gowning and de-gowning important in an ISO 1 cleanroom?

A: Gowning and de-gowning procedures are critical in maintaining the cleanliness of the ISO 1 cleanroom. Individuals must wear appropriate clothing, including gloves, hoods, and face masks, to prevent the release of any particles.

Q: What industries require ISO 1 cleanrooms?

A: Industries that require a controlled environment for sensitive products or processes, such as pharmaceuticals, biotechnology, and electronics, require ISO 1 cleanrooms.

Q: What are the benefits of ISO 1 cleanrooms?

A: The benefits of ISO 1 cleanrooms include product quality, health and safety, and compliance with regulations and guidelines.

Q: How does an ISO 1 cleanroom contribute to creating a safe work environment?

A: An ISO 1 cleanroom provides a safe work environment by preventing the release of harmful particles, such as bacteria and viruses, which could be harmful to workers.

Q: What regulations and guidelines must be followed to maintain an ISO 1 cleanroom?

A: Industries that require a controlled environment must comply with strict regulations and guidelines, such as those set by the FDA and ISO. ISO 1 cleanrooms ensure compliance with these regulations and guidelines.

In conclusion, an ISO 1 cleanroom is a highly controlled and ultra-clean environment designed to limit airborne particles, bacteria, and other microorganisms. To maintain an ISO 1 cleanroom, strict requirements must be met, including air filtration, positive pressure, gowning and de-gowning procedures, and airflow control. The benefits of an ISO 1 cleanroom include product quality, health and safety, and compliance with regulations and guidelines. For industries that require a controlled environment for sensitive products or processes, such as pharmaceuticals, biotechnology, and electronics, an ISO 1 cleanroom is an essential element to ensure the safety and quality of their products.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Portable Clean Room, ISO 8 Clean Room, Cleanroom Workshop, Cleanroom ISO Standards, Clean Room Engineering Design, Clean Room for Physics Laboratory, Design of Dust-Free Clean Room.