Design of Dust-Free Clean Room: An Overview of Requirements and Best Practices

- 2024-05-28

- View 12

Design of dust-free clean room is crucial for industries that require controlled environments. Learn about the requirements and best practices for designing a clean room.

Introduction:

A dust-free clean room is an essential facility for many industries, including pharmaceuticals, biotechnology, electronics, and aerospace. The design of dust-free clean room is critical to ensure that the controlled environment meets the required standards. The clean room design must consider the process requirements, the type of particles that need to be controlled, the airflow requirements, and the personnel and equipment entering the clean room. In this article, we will discuss the essential requirements and best practices for designing a dust-free clean room.

Headings:

Requirements for Design of Dust-Free Clean Room

Best Practices for Designing a Dust-Free Clean Room

Key Elements of Clean Room Design

Types of Clean Room Design

HVAC Design for Clean Rooms

Clean Room Certification and Testing

Common FAQs about Design of Dust-Free Clean Room

Requirements for Design of Dust-Free Clean Room:

To design a dust-free clean room, you need to consider the following requirements:

Contamination Control: The primary objective of a clean room is to maintain a controlled environment that is free from airborne contaminants. The design of a clean room must minimize the generation and entry of contaminants and ensure that the contaminants are effectively removed from the environment.

Airflow Control: The airflow within a clean room must be carefully controlled to prevent the accumulation and spread of contaminants. The design must consider the type and location of the air supply and return, the velocity of the air, and the direction of the airflow.

Environmental Control: The design of a clean room must provide precise environmental control, including temperature, humidity, and pressure control. The clean room must also be designed to prevent the entry of external contaminants.

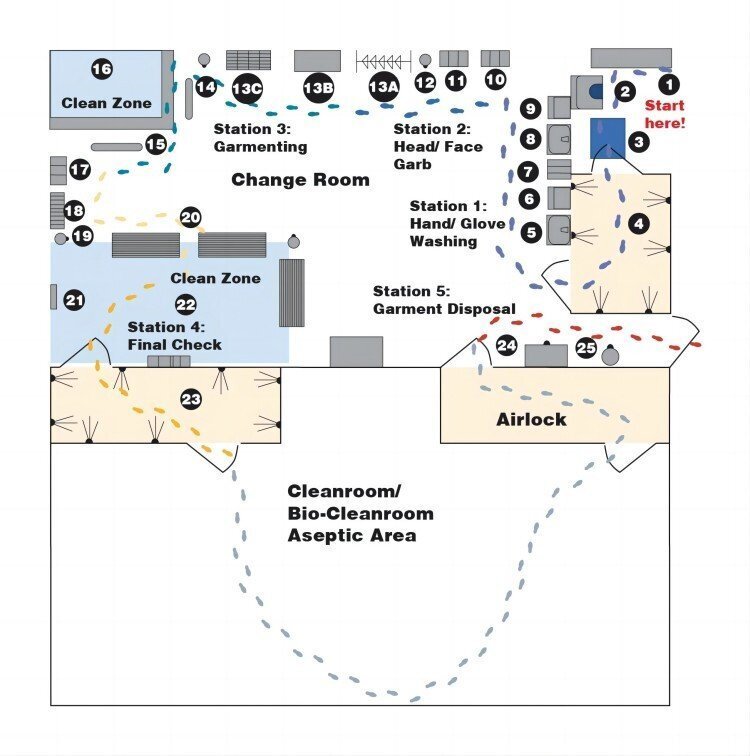

Personnel and Equipment Control: The design of a clean room must include measures to control the entry and exit of personnel and equipment to prevent the introduction of contaminants. This includes gowning requirements, airlocks, and equipment decontamination.

Best Practices for Designing a Dust-Free Clean Room:

The following best practices can help ensure that the clean room design meets the required standards:

Design for Functionality: The design of a clean room must consider the process requirements and ensure that the environment is suitable for the intended operations. The design must also consider the ease of cleaning and maintenance.

Use Appropriate Materials: The materials used in the construction of a clean room must be compatible with the environment and the cleaning agents used. The materials must also be non-shedding and free from particles that could contaminate the environment.

Design for Airflow Control: The design of the clean room must consider the airflow requirements, including the type and location of the air supply and return, and the direction of the airflow. The design must also consider the filtration and air exchange requirements.

Consider Personnel and Equipment Control: The design must include measures to control the entry and exit of personnel and equipment, including airlocks, gowning requirements, and equipment decontamination.

Key Elements of Clean Room Design:

The following key elements are essential for a successful clean room design:

Clean Room Classification: Clean rooms are classified based on the maximum allowable number of particles per cubic meter. The clean room classification determines the level of environmental control required for the intended operations.

Airflow Control: The airflow within a clean room must be carefully controlled to prevent the accumulation and spread of contaminants. The design must consider the type and location of the air supply and return, the velocity of the air, and the direction of the airflow.

Filtration and Air Exchange: The clean room must have an appropriate filtration system that can capture particles of the required size. The air exchange rate must also be designed to ensure that the environment meets the required cleanliness level.

HVAC System: The HVAC system must be designed to provide precise environmental control, including temperature, humidity, and pressure control. The HVAC system must also be designed to minimize the generation and spread of contaminants.

Types of Clean Room Design:

The following are the types of clean room design:

Modular Clean Room: Modular clean rooms are pre-engineered, prefabricated clean rooms that can be easily installed and customized. These types of clean rooms are suitable for applications that require a smaller clean room or for temporary clean room requirements.

Hardwall Clean Room: Hardwall clean rooms are permanent structures that are built on-site. These types of clean rooms are suitable for applications that require larger clean rooms or for long-term clean room requirements.

Softwall Clean Room: Softwall clean rooms are temporary structures that are made of flexible materials. These types of clean rooms are suitable for applications that require a smaller clean room or for temporary clean room requirements.

HVAC Design for Clean Rooms:

The HVAC system is one of the most critical components of a clean room design. The HVAC system must provide precise environmental control and minimize the generation and spread of contaminants. The following are the key considerations for HVAC design for clean rooms:

Airflow and Pressure Control: The airflow and pressure within a clean room must be carefully controlled to prevent the spread of contaminants. The HVAC system must be designed to provide the required air exchange rate and maintain the required pressure differentials between the clean room and adjacent areas.

Filtration System: The HVAC system must include an appropriate filtration system that can capture particles of the required size. The filtration system must also be designed to minimize the generation and spread of contaminants.

Temperature and Humidity Control: The HVAC system must provide precise temperature and humidity control to ensure that the environment meets the required standards.

Clean Room Certification and Testing:

Clean room certification and testing are essential to ensure that the clean room meets the required standards. The following are the key steps for clean room certification and testing:

Initial Qualification: The clean room must undergo an initial qualification process that includes design review, installation qualification, and operational qualification.

Routine Monitoring: The clean room must undergo routine monitoring to ensure that the environment meets the required standards. The monitoring must include particle counting, microbial monitoring, and environmental monitoring.

Requalification: The clean room must undergo requalification after any significant changes to the design or operations.

Common FAQs about Design of Dust-Free Clean Room:

Q: What is a clean room?

A: A clean room is a controlled environment that is designed to minimize the generation and spread of contaminants.

Q: What are the requirements for a clean room design?

A: The requirements for a clean room design include contamination control, airflow control, environmental control, and personnel and equipment control.

Q: What are the types of clean room design?

A: The types of clean room design include modular clean room, hardwall clean room, and softwall clean room.

Conclusion:

Design of dust-free clean room is critical to ensure that industries that require controlled environments can maintain their standards. The design must consider the process requirements, the type of particles that need to be controlled, the airflow requirements, and the personnel and equipment entering the clean room. By following the best practices and requirements discussed in this article, industries can design a dust-free clean room that meets the required standards and ensures the quality of their products.

More of your interest