Cleanroom ISO Standards: Understanding the Basics

- 2024-01-31

- View 10

Cleanrooms are critical environments used in various industries such as pharmaceuticals, biotechnology, aerospace, and electronics manufacturing. These environments require strict control of contamination levels to protect products, equipment, and personnel. The International Organization for Standardization (ISO) has developed various standards to ensure that cleanrooms meet certain requirements. In this article, we will discuss the basics of cleanroom ISO standards, their importance, and how they affect various industries.

Introduction to Cleanroom ISO Standards

ISO is an international standard-setting body that develops and publishes standards for various industries. ISO standards provide a set of guidelines that help organizations maintain quality, safety, and efficiency Cleanroom ISO standards are a set of guidelines that help manufacturers and operators maintain cleanliness in their environments. These standards ensure that cleanrooms meet certain criteria for air cleanliness, particle counts, and environmental control.

Cleanroom ISO Classification Standards

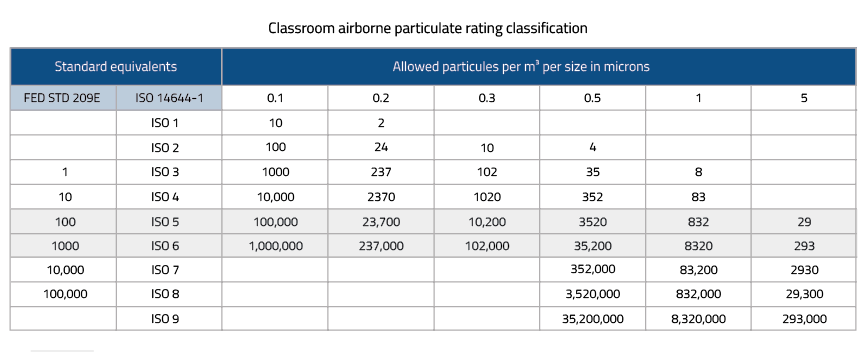

Cleanroom ISO standards classify cleanrooms based on the maximum allowable number of particles per cubic meter of air. The classification system ranges from ISO 1 (the cleanest) to ISO 9 (the least clean). The classification system is based on the number and size of particles in the air. ISO 1 cleanrooms have the fewest number of particles, while ISO 9 cleanrooms have the most.

Importance of Cleanroom ISO Standards

Cleanroom ISO standards are important because they ensure that the environment is suitable for its intended use. In industries such as pharmaceuticals and biotechnology, cleanrooms are essential for the production of safe and effective products. Cleanroom ISO standards help to minimize the risk of contamination, which can have serious consequences. Contamination can result in product defects, equipment damage, and even health risks to personnel.

Cleanroom ISO Standards and the Pharmaceutical Industry

The pharmaceutical industry relies heavily on cleanrooms to ensure the safety and effectiveness of its products. Cleanroom ISO standards are crucial for pharmaceutical manufacturing, as even minor contamination can compromise the quality of the product. The pharmaceutical industry follows Good Manufacturing Practices (GMP) guidelines to ensure that products are manufactured in a clean and controlled environment.

Cleanroom ISO Standards and the Electronics Industry

The electronics industry also requires cleanroom environments to manufacture sensitive electronic components. Cleanroom ISO standards are important for the electronics industry because even small particles can damage delicate electronic components. Cleanrooms help to protect products from contamination, which can lead to product failure or malfunction.

Cleanroom ISO Standards and the Aerospace Industry

The aerospace industry also relies heavily on cleanrooms to manufacture critical components such as satellites, rockets, and aircraft. Cleanroom ISO standards are important for the aerospace industry because contamination can have serious consequences. Even minor contamination can cause equipment failure or compromise the safety of personnel.

Cleanroom ISO Standards and Environmental Control

Cleanroom ISO standards also include guidelines for environmental control. Cleanrooms require strict control of temperature, humidity, and air pressure to maintain a clean environment. Environmental control is important because changes in temperature or humidity can affect particle counts and compromise the cleanliness of the environment.

Cleanroom ISO Standards and Personal Protective Equipment

Cleanroom ISO standards also require the use of personal protective equipment (PPE) such as gowns, gloves, and masks. PPE is essential to prevent contamination from personnel. PPE should be worn properly and changed frequently to prevent contamination.

Cleanroom ISO Standards and Cleaning Procedures

Cleanroom ISO standards also require strict cleaning procedures to maintain a clean environment. Cleaning procedures should be performed regularly using approved cleaning agents and equipment. Cleaning procedures should be documented and reviewed regularly to ensure that they are effective.

Cleanroom ISO Standards and Training

Cleanroom ISO standards also require that personnel receive proper training on the use of equipment, cleaning procedures, and PPE. Proper training ensures that personnel understand the importance of maintaining a clean environment and how to do so effectively.

Cleanroom ISO Standards and Certification

Cleanroom ISO standards also provide a framework for certification Cleanroom certification is a process that involves testing and evaluation of the cleanroom environment to ensure that it meets ISO standards. Cleanroom certification provides assurance to customers and regulatory agencies that the environment is suitable for its intended use.

Cleanroom ISO Standards and Cost

Implementing cleanroom ISO standards can be costly, as it requires specialized equipment, training, and certification. However, the cost of not implementing these standards can be even higher. Contamination can result in product defects, equipment damage, and even health risks to personnel. Implementing cleanroom ISO standards can help to prevent these issues and ensure a safe and controlled environment.

Cleanroom ISO Standards and Future Developments

Cleanroom ISO standards continue to evolve to meet the changing needs of various industries. The ISO 14644 standard, which outlines the classification system for cleanrooms, was recently updated in 2015. The updated standard provides more specific guidelines for particle counts and environmental control.

FAQs

What is a cleanroom?

A cleanroom is a controlled environment used in various industries to minimize the risk of contamination and protect products, equipment, and personnel.

What are cleanroom ISO standards?

Cleanroom ISO standards are a set of guidelines that help manufacturers and operators maintain cleanliness in their environments. These standards ensure that cleanrooms meet certain criteria for air cleanliness, particle counts, and environmental control.

Why are cleanroom ISO standards important?

Cleanroom ISO standards are important because they ensure that the environment is suitable for its intended use. Contamination can have serious consequences such as product defects, equipment damage, and even health risks to personnel.

What industries rely on cleanroom environments?

Industries such as pharmaceuticals, biotechnology, aerospace, and electronics manufacturing rely heavily on cleanroom environments.

What is cleanroom certification?

Cleanroom certification is a process that involves testing and evaluation of the cleanroom environment to ensure that it meets ISO standards. Cleanroom certification provides assurance to customers and regulatory agencies that the environment is suitable for its intended use.

Conclusion

Cleanroom ISO standards are essential for maintaining clean and controlled environments in various industries. These standards provide guidelines for air cleanliness, particle counts, environmental control, personal protective equipment, and cleaning procedures. Implementing these standards can be costly, but the cost of not implementing them can be even higher. Cleanroom ISO standards continue to evolve to meet the changing needs of various industries, and certification provides assurance that the environment is suitable for its intended use.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Clean Workshop Air Shower, Cleanroom Engineering Company, Clean Room Price, Class 1000 Clean Room, Clean Room Engineering Design, Cosmetics Clean Room Engineering, Laboratory Clean Room.