Clean Room Standards: Ensuring Quality and Safety in Sensitive Environments

- 2024-05-26

- View 13

Clean rooms are highly controlled environments used in various industries to minimize contamination and maintain product quality. These facilities must meet specific standards to ensure the safety and integrity of the products produced within them. In this article, we will explore the clean room standard, its importance, and the various components that make up a clean room.

What is a Clean Room?

A clean room is a specially designed environment that has a controlled level of contamination. The contamination can come from various sources, including people, equipment, and processes. The goal of a clean room is to limit the amount of contamination to a level that will not adversely affect the product or process being performed within the room.

Types of Contaminants in Clean Rooms

Contaminants in a clean room can be classified into three categories: particulate, chemical, and biological. Particulate contamination consists of dust, fibers, and other small particles that can be introduced into the clean room environment Chemical contamination can come from cleaning agents, solvents, and other chemicals used in the manufacturing process. Biological contamination includes bacteria, viruses, and other microorganisms that can be harmful to humans or products.

Clean Room Standards

Clean room standards are guidelines set by regulatory bodies that outline the requirements for designing, constructing, operating, and maintaining a clean room facility. The standards specify the maximum allowable levels of particulate and microbial contamination in the air and on surfaces within the clean room. Compliance with these standards ensures that the products produced in the clean room are safe, consistent, and of high quality.

ISO Clean Room Standards

The International Organization for Standardization (ISO) has developed a series of clean room standards that provide a framework for the design, construction, and operation of clean rooms These standards include ISO 14644-1, ISO 14644-2, and ISO 14644-3. ISO 14644-1 specifies the classification of air cleanliness in clean rooms while ISO 14644-2 outlines the testing and monitoring requirements for clean rooms. ISO 14644-3 provides guidance on the design, construction, and operation of clean rooms.

Other Clean Room Standards

Other organizations have developed their own clean room standards, including the United States Pharmacopeia (USP), the European Union Good Manufacturing Practice (EU GMP), and the Federal Standard 209E. These standards are used in specific industries and are designed to meet the unique needs of those industries.

Components of a Clean Room

Clean rooms are made up of several components that work together to maintain the cleanliness and safety of the environment.

HVAC System

The HVAC (heating, ventilation, and air conditioning) system is responsible for maintaining the air quality in the clean room. The system filters and circulates the air, removing contaminants and maintaining the required temperature and humidity levels.

Clean Room Clothing

Clean room clothing, including gowns, gloves, and face masks, is designed to limit the amount of particulate and microbial contamination introduced into the clean room environment.

Clean Room Equipment

All equipment used in the clean room must be designed and constructed to minimize the introduction of contaminants into the environment. Equipment is regularly inspected and cleaned to ensure it meets the required standards.

Clean Room Procedures

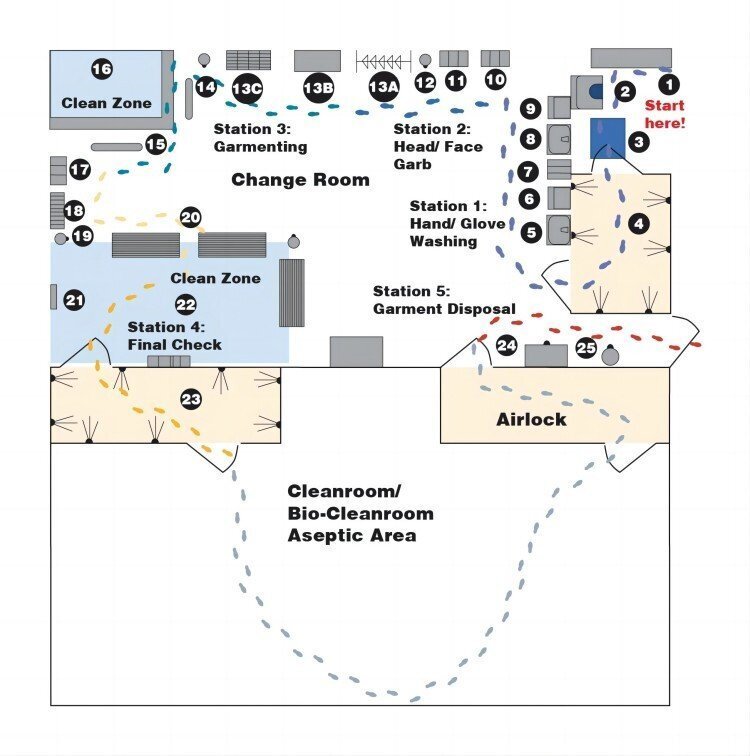

Strict procedures must be followed when entering and exiting a clean room to prevent contamination. This includes the use of airlocks, gowning procedures, and hand washing.

Conclusion

Clean rooms are essential in industries where contamination can lead to significant consequences, such as in the pharmaceutical, semiconductor, and aerospace industries. Compliance with clean room standards ensures the safety and quality of products produced in these environments. The components of a clean room, including the HVAC system, clean room clothing, equipment, and procedures, work together to create a highly controlled environment that minimizes the introduction of contaminants. The ISO clean room standards provide a framework for the design, construction, and operation of these facilities, while other standards, such as USP and EU GMP, are specific to certain industries.

In conclusion, clean room standards are essential in maintaining the safety and quality of products produced in sensitive environments. The components of a clean room, including the HVAC system, clean room clothing, equipment, and procedures, work together to create a highly controlled environment that minimizes the introduction of contaminants. Compliance with these standards ensures that products produced in these facilities are safe, consistent, and of high quality.

FAQs

What industries require the use of clean rooms?

Industries such as pharmaceuticals, semiconductors, aerospace, and medical device manufacturing require the use of clean rooms.

What are the types of contaminants in clean rooms?

The types of contaminants in clean rooms are particulate, chemical, and biological.

What are ISO clean room standards?

ISO clean room standards provide a framework for the design, construction, and operation of clean rooms, with ISO 14644-1 specifying the classification of air cleanliness, ISO 14644-2 outlining testing and monitoring requirements, and ISO 14644-3 providing guidance on the design, construction, and operation of clean rooms.

What is the role of the HVAC system in a clean room?

The HVAC system is responsible for maintaining the air quality in the clean room, filtering and circulating the air, and maintaining the required temperature and humidity levels.

What is the purpose of clean room clothing?

Clean room clothing, including gowns, gloves, and face masks, is designed to limit the amount of particulate and microbial contamination introduced into the clean room environment.