Clean Room Grade: Understanding the Levels and Standards

- 2024-01-04

- View 13

Clean rooms are controlled environments that are designed to limit the introduction, generation, and retention of airborne particles and other contaminants. These rooms are essential in industries that require high levels of cleanliness, such as pharmaceuticals, biotechnology, electronics, and aerospace. To ensure consistency and uniformity in the level of cleanliness clean rooms are classified into different grades or classes. In this article, we will explore the different clean room grades, their standards, and their applications.

Introduction to Clean Room Grade

Clean room grade refers to the level of cleanliness required in a clean room environment The grade is determined by the number and size of particles per cubic meter of air. The smaller the particle size and the lower the concentration, the higher the clean room grade.

Clean Room Grades and Standards

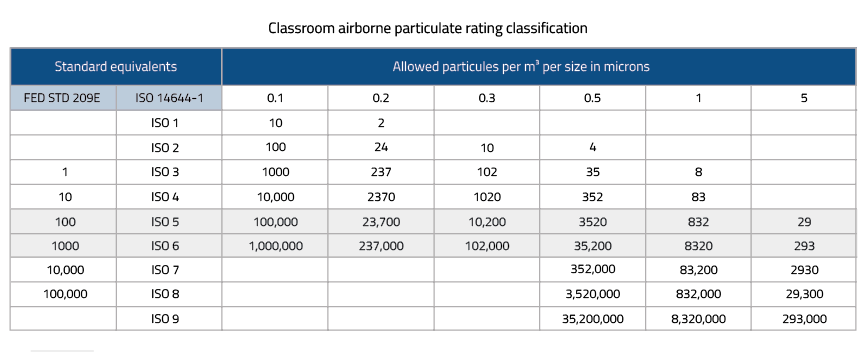

Clean room grades are defined by various international standards, including ISO 14644 and Federal Standard 209E. These standards classify clean rooms based on the maximum allowable concentration of particles per cubic meter of air, as shown in the following table:

Clean Room Grade Maximum Allowable Concentration of Particles (per cubic meter of air)

ISO 1 (Class 1) 10

ISO 2 (Class 10) 100

ISO 3 (Class 100) 1,000

ISO 4 (Class 1,000) 10,000

ISO 5 (Class 10,000) 100,000

ISO 6 (Class 100,000) 1,000,000

ISO 7 (Class 1,000,000) 10,000,000

ISO 8 (Class 10,000,000) ≥ 35,000,000

Each clean room grade has specific requirements for air changes per hour, temperature, humidity, and pressure differentials.

Applications of Clean Room Grades

Clean room grades are used in various industries that require a high level of cleanliness to maintain product quality and safety. The following are some examples of applications for different clean room grades:

ISO 1-5

ISO 1-5 clean room grades are used in industries that require extremely high levels of cleanliness, such as microelectronics, semiconductor manufacturing, and nanotechnology.

ISO 6-8

ISO 6-8 clean room grades are used in industries that require a lower level of cleanliness, such as pharmaceuticals, biotechnology, medical devices, and aerospace.

Clean Room Design and Maintenance

Design and maintenance are crucial aspects of clean room operation. Clean rooms must be designed to meet the requirements of the desired clean room grade. The design should consider the airflow, the placement of equipment, the location of personnel, and the material used for construction. Regular maintenance is also essential to ensure that the clean room continues to meet the required cleanliness level.

FAQs

What is the difference between ISO 14644 and Federal Standard 209E?

ISO 14644 is an international standard, while Federal Standard 209E is a US standard that has been replaced by ISO 14644.

What is the importance of clean room grades?

Clean room grades are important to maintain product quality and safety in industries that require high levels of cleanliness.

What are some industries that use clean rooms?

Clean rooms are used in various industries, such as microelectronics, semiconductor manufacturing, nanotechnology, pharmaceuticals, biotechnology, medical devices, aerospace, and more.

What are some factors to consider when designing a clean room?

Airflow, equipment placement, personnel location, and construction materials are some factors to consider when designing a clean room.

How often should clean rooms be maintained?

Clean rooms should be regularly maintained to ensure that they continue to meet the required cleanliness level. The maintenance frequency depends on the specific requirements of the industry and clean room grade.

Conclusion

Clean room grades play a critical role in industries that require high levels of cleanliness. Different clean room grades have specific requirements for particle concentration, air changes per hour, temperature, humidity, and pressure differentials. The design and maintenance of clean rooms are crucial to ensure that the clean room continues to meet the required cleanliness level.