Understanding ISO 5 Cleanrooms: Standards, Benefits, and Maintenance

- 2024-04-29

- View 14

If you're in the pharmaceutical, biotechnology, or semiconductor industries, you must have heard of ISO 5 cleanrooms These are specialized environments where the concentration of airborne particles is strictly controlled. The International Organization for Standardization (ISO) sets guidelines for the cleanliness of cleanrooms, and ISO 5 is the cleanest class. In this article, we will provide a comprehensive guide to ISO 5 cleanrooms, covering everything from what they are, how they work, and their applications.

What is an ISO 5 Cleanroom?

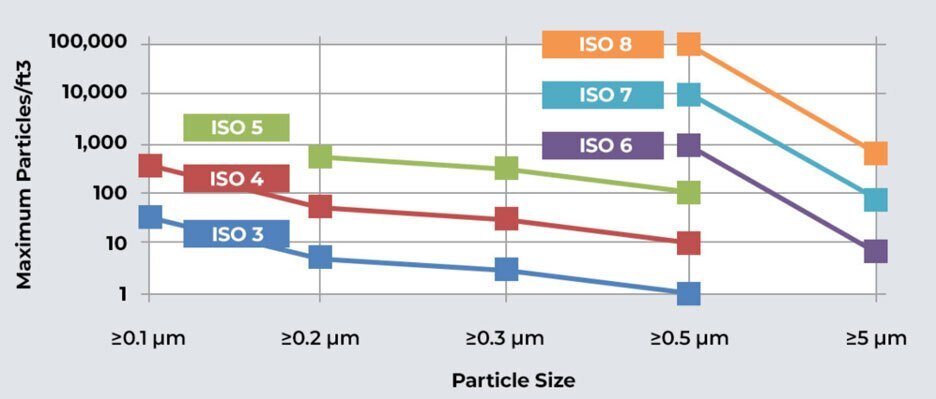

An ISO 5 cleanroom is a controlled environment where the concentration of airborne particles is limited to a specific level. According to the ISO standard, a cleanroom must have no more than 3,520 particles of size 0.5 microns or larger per cubic meter of air. This is equivalent to a room with no more than one particle per 283 cubic feet of air.

How does an ISO 5 Cleanroom Work?

An ISO 5 cleanroom works by using a combination of high-efficiency particulate air (HEPA) filters and positive pressure. The HEPA filters remove particles from the air, while positive pressure ensures that clean air flows out of the room, preventing outside air from entering. The room's walls, floors, and ceilings are made of materials that don't shed particles, such as stainless steel or plastic laminates.

Applications of ISO 5 Cleanrooms

ISO 5 cleanrooms are used in industries where particle contamination can lead to product failure or health risks. Here are some applications of ISO 5 cleanrooms:

Pharmaceutical Industry

Pharmaceutical companies use ISO 5 cleanrooms to manufacture drugs, including sterile injectable drugs, ointments, and creams. Cleanrooms are also used for aseptic processing, which involves filling sterile drugs into vials or syringes.

Biotechnology Industry

The biotechnology industry uses cleanrooms to manufacture biologics, including monoclonal antibodies, vaccines, and cell therapies. These products are highly sensitive to contamination, so it's essential to produce them in a clean environment.

Semiconductor Industry

The semiconductor industry uses cleanrooms to manufacture microchips and other electronic components. Even small particles can damage these components, so a clean environment is critical for ensuring product quality.

Medical Device Industry

The medical device industry uses cleanrooms to manufacture implantable devices, such as pacemakers and artificial joints. These products must be manufactured in a sterile environment to prevent infection.

Design Considerations for ISO 5 Cleanrooms

When designing an ISO 5 cleanroom, several factors must be considered:

Airflow

Airflow is critical in an ISO 5 cleanroom. The room must be designed so that air flows from clean to dirty areas, preventing contaminants from entering the room.

Filtration

HEPA filters are the most commonly used filters in cleanrooms. They remove particles as small as 0.3 microns with an efficiency of 99.97%.

Material Selection

The materials used in an ISO 5 cleanroom must be non-shedding and easy to clean. Stainless steel and plastic laminates are common materials used in cleanroom construction.

Personnel

Personnel who enter the cleanroom must wear cleanroom garments, including gowns, gloves, and face masks. They must also undergo training on cleanroom procedures to prevent contamination.

Maintaining an ISO 5 Cleanroom

Maintaining an ISO 5 cleanroom is essential to ensure that it remains within the ISO standard. Here are some tips for maintaining a cleanroom:

Regular Cleaning

Cleanrooms must be cleaned regularly to remove contaminants. This includes wiping down surfaces and equipment with cleanroom-approved disinfectants and vacuuming the floors with specialized equipment.

Air Quality Testing

Regular air quality testing is essential to ensure that the cleanroom is within the ISO 5 standard. Air samplers are used to collect air samples, which are analyzed for particle concentration.

Equipment Maintenance

Equipment used in the cleanroom must be maintained regularly to prevent particle generation. This includes replacing filters, cleaning equipment, and performing preventative maintenance.

Benefits of Using an ISO 5 Cleanroom

Using an ISO 5 cleanroom provides several benefits, including:

Improved Product Quality

Cleanrooms help ensure that products are manufactured in a controlled environment, reducing the risk of contamination and improving product quality.

Regulatory Compliance

Industries that require cleanrooms, such as the pharmaceutical industry, must comply with regulatory standards. Using an ISO 5 cleanroom helps ensure compliance with these standards.

Increased Productivity

Cleanrooms provide a controlled environment that reduces the risk of product failure, increasing productivity by reducing the need for rework and downtime.

Conclusion

ISO 5 cleanrooms play a critical role in industries where particle contamination can lead to product failure or health risks. By using HEPA filters and positive pressure, ISO 5 cleanrooms provide a controlled environment that meets strict particle concentration standards. Maintaining a cleanroom requires regular cleaning, air quality testing, and equipment maintenance. The benefits of using an ISO 5 cleanroom include improved product quality, regulatory compliance, and increased productivity.

FAQs

What is the difference between an ISO 5 and ISO 6 cleanroom?

An ISO 5 cleanroom has a stricter particle concentration standard than an ISO 6 cleanroom. ISO 5 cleanrooms must have no more than 3,520 particles of size 0.5 microns or larger per cubic meter of air, while ISO 6 cleanrooms can have up to 35,200 particles.

How often should a cleanroom be cleaned?

Cleanrooms should be cleaned daily or after each use, depending on the level of contamination.

What is a cleanroom garment?

A cleanroom garment is a specialized garment worn by personnel who enter the cleanroom. It includes a gown, gloves, and face mask to prevent contamination.

Can a cleanroom be used for multiple products?

Cleanrooms can be used for multiple products, but the cleaning and disinfection procedures must be modified between products to prevent cross-contamination.

What is the cost of building an ISO 5 cleanroom?

The cost of building an ISO 5 cleanroom depends on several factors, including the size of the room, the level of cleanliness required, and the materials used in construction. It can range from tens of thousands to millions of dollars.