Cleanroom Classification Of Class 100 Cleanliness

- 2024-04-30

- View 34

The air flow in a Class 100 cleanroom is laminar, where the air flows in the same horizontal direction at a uniform cross-sectional velocity, not unlike the concept of laminar flow in fluid dynamics.

Vertical laminar flow and side return air. Compared with the flocculation type (i.e., air flows in an uneven flow line at an uneven speed) in clean rooms of class 100 or more, it has the following effects

However, the high price of the equipment makes it difficult for some small and medium-sized factories to afford.

However, the price of the equipment is too high for some small and medium-sized manufacturers to afford, and the maintenance cost is also very high.

Cleanroom Class 100 Cleanliness: The number of dust particles ≥0.1 micron needs to be less than 100.

Cleanroom class 100 provides clean environment for photolithography processes and other experiments in which dust particles may affect quality of processed or measured samples. The air in the cleanroom is filtered several times before leaving the cleanroom so that there is less than 100 particles in a cubic meter. The quality of the air is constantly monitored by the particle monitoring system. The purity of the air in the vertical flow benches is one order of magnitude better. The cleanroom accommodates basic photolithography, assembly and surface characterization tools.

The need for purity within microelectronics and aerospace piping systems is a common topic in our industry.

Cleanliness must be guaranteed Cleanrooms and the welders and fabricators who work in them are essential to meeting the strict requirements in these applications.

Companies love bragging on their cleanroom capabilities. We certainly do. But let’s dig deeper. What makes a cleanroom a cleanroom? What systems must be in place to maintain the environment? How do those systems work? What does it mean for customers?

Vetting cleanroom welders is a common challenge among customers in our industry. We believe transparency can lessen that burden.

Even the smallest microscopic particles can cause serious problems if they contaminate ultra-high purity systems. Cleanrooms are rated based on how well they keep particles out of the air.

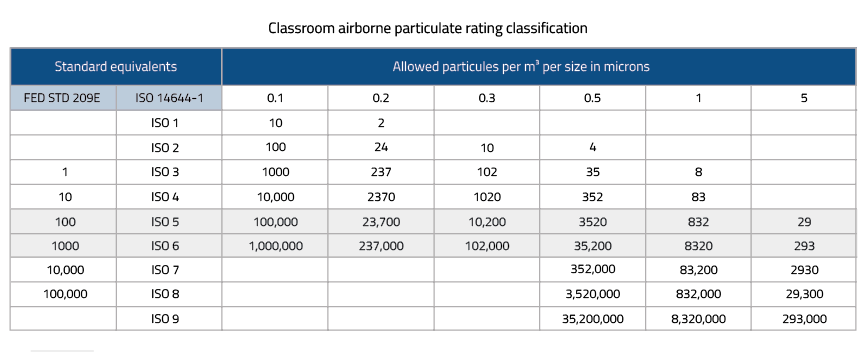

The chart below includes the International Organization for Standards (ISO) cleanroom classes. The classes are described in ISO 14644-1. In addition, the classes are shown alongside their Federal Standard 209E equivalents. (While FED STD 209E was canceled in 2001 in favor of ISO 14644, it remains the preferred way to express cleanroom airborne particulate standards in the U.S.)

As the highlighted portions of the chart indicate, our cleanroom is Class 100- and Class 1000-rated (ISO 5 and ISO 6).

Cleanroom protocol

Anyone entering the cleanroom must gown up head-to-toe immediately. We supply booties that fit over shoes and boots while keeping a sticky mat at the entrance to the gowning area to snare any lingering particles on footwear or the floor.

Segregation of raw materials is also critical in process piping, whether for a high-purity application or not. The corrosion-resistant 316L stainless steel we use for cleanroom welding and fabrication projects is always kept separate from ferritic materials to eliminate corrosion risk.

No ferritic materials are allowed in the cleanroom at any time for the same reason.

We also have a strict policy for the welding and quality testing equipment used in the cleanroom: Once it’s in, it stays in.

When we finish a project, it heads to a packaging station within the cleanroom. There, we double-bag and seal the work. The package is filled with an inert gas to guarantee it stays as clean during shipping as it was during manufacturing.

How do you clean a cleanroom?

It’s all about ensuring no particles or moisture enter the space.

That’s why we never use water to clean equipment or surfaces. Instead, we use 70% isopropyl alcohol. And no paper towels or flannel rags, either. The risk of contamination is too high with those materials, so we only use synthetic cleanroom wipes.

ISO 7 Cleanrooms are special temperature controlled rooms where Temperature, Relative Humidity and Particle Count are regulated. In order to attain and maintain the desired conditions in the room, Air Conditioning is Integrated with Air Filtration.

Air Filtration takes place at sub-micronic levels, 0.3micron level to be precise, at a very high efficiency of 99.99%. To prevent contaminants from entering the room, the room is maintained at a positive pressure relative to the adjacent rooms.