ISO 9 Cleanroom: Understanding the Basics of a Controlled Environment

- 2024-05-03

- View 26

An ISO 9 cleanroom is a controlled environment that adheres to specific cleanliness standards defined by the International Organization for Standardization (ISO). It is designed to limit the concentration of airborne particles and control other environmental parameters, such as temperature, humidity, and air pressure. ISO 9 cleanrooms are considered "low-level" cleanrooms, suitable for applications that require a controlled environment but with less stringent cleanliness requirements compared to higher ISO classes.

Key Characteristics of an ISO 9 Cleanroom

ISO 9 cleanrooms exhibit several key characteristics, including:

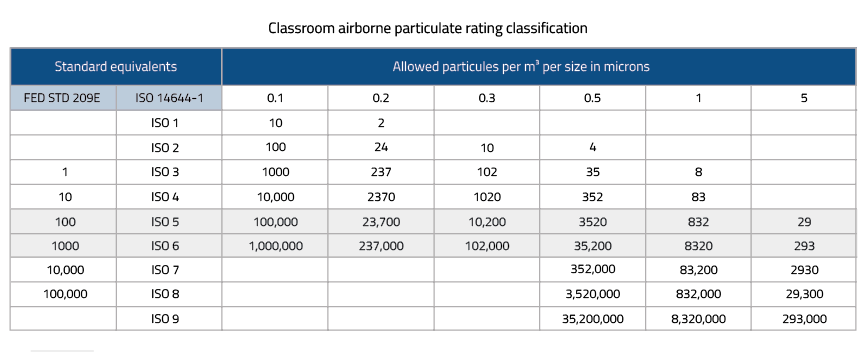

Airborne Particle Control: ISO 9 cleanrooms are designed to limit the concentration of airborne particles larger than 5 micrometers to 35,200 particles per cubic meter (ISO Class 9 classification).

Environmental Control: These cleanrooms maintain controlled environmental parameters such as temperature, humidity, and air pressure to ensure stability and prevent deviations that could impact processes or products.

Ventilation Systems: ISO 9 cleanrooms incorporate efficient ventilation systems that provide an adequate supply of filtered air, ensuring continuous air circulation and minimizing the presence of contaminants.

Surface Cleanliness: Surfaces within ISO 9 cleanrooms are regularly cleaned and maintained to prevent particle accumulation and minimize potential contamination sources.

Importance of ISO 9 Cleanrooms

ISO 9 cleanrooms are essential for industries where a controlled environment is necessary, but the level of cleanliness required is relatively lower. These cleanrooms provide several important benefits:

Contamination Control: ISO 9 cleanrooms help prevent particulate contamination from impacting sensitive processes, equipment, or products, ensuring consistent quality and reliability.

Process Consistency: By maintaining controlled environmental conditions, ISO 9 cleanrooms contribute to process stability and consistency, reducing the risk of variations or deviations that could affect product performance.

Protection of Personnel and Products: ISO 9 cleanrooms safeguard both personnel and products by minimizing exposure to external contaminants, enhancing worker safety, and preserving product integrity.

Regulatory Compliance: Compliance with ISO 9 cleanroom standards demonstrates a commitment to meeting industry regulations and quality guidelines, ensuring the highest level of professionalism and product quality.

Applications of ISO 9 Cleanrooms

ISO 9 cleanrooms find application in a wide range of industries and processes, including:

Electronics Assembly: ISO 9 cleanrooms provide controlled environments for electronic assembly, ensuring the protection of delicate electronic components from particulate contamination.

Packaging and Testing: Industries involved in product packaging and testing, such as food and pharmaceutical industries, utilize ISO 9 cleanrooms to maintain clean and controlled environments for packaging and quality control processes.

Optics and Photonics: Optical component manufacturing, precision optics assembly, and photonics industries benefit from ISO 9 cleanrooms to ensure optimal cleanliness and accuracy in their processes.

Research and Development: ISO 9 cleanrooms are also utilized in research and development facilities where a controlled environment is required for experimentation, prototyping, and testing.

Design Considerations for ISO 9 Cleanrooms

Designing an ISO 9 cleanroom involves careful consideration of several factors, including:

Air Filtration and Ventilation: Proper selection and placement of HEPA (High-Efficiency Particulate Air) filters and efficient ventilation systems to maintain the desired cleanliness levels and air quality.

Material Selection: Selection of appropriate materials for cleanroom surfaces, furnishings, and fixtures that are easy to clean, resistant to contamination, and compatible with cleanroom protocols.

Airflow Patterns: Designing airflow patterns to minimize turbulence, prevent particle accumulation, and facilitate the removal of contaminants from the controlled environment.

Monitoring and Control Systems: Implementation of robust monitoring and control systems to continuously measure and maintain environmental parameters, ensuring consistency and adherence to ISO 9 standards.

Maintaining ISO 9 Cleanroom Standards

To ensure ISO 9 cleanrooms continue to meet the required standards, regular maintenance and monitoring are essential. Some key practices include:

Cleaning and Disinfection: Regular cleaning and disinfection of surfaces, equipment, and furnishings to prevent particle buildup and minimize potential contamination sources.

Filter Replacement: Scheduled replacement of HEPA filters to maintain filtration efficiency and ensure the removal of airborne particles within the specified limits.

Environmental Monitoring: Continuous monitoring of temperature, humidity, particle counts, and other critical parameters to detect deviations and promptly address any issues.

Training and Protocols: Comprehensive training programs for cleanroom personnel, emphasizing proper gowning, behavior, and adherence to cleanroom protocols to minimize contamination risks.

ISO 9 Cleanroom Certification and Compliance

Certification and compliance with ISO 9 cleanroom standards involve thorough assessments and audits conducted by accredited organizations. These evaluations verify that the cleanroom meets the specified requirements in terms of cleanliness, environmental control, and adherence to ISO guidelines.

Benefits of ISO 9 Cleanrooms

ISO 9 cleanrooms offer several benefits, including:

Cost-Effectiveness: Compared to higher ISO classes, ISO 9 cleanrooms require less stringent design, construction, and operational expenses, making them a cost-effective solution for industries with moderate cleanliness requirements.

Flexibility: ISO 9 cleanrooms provide a balance between controlled environments and operational flexibility, allowing industries to adapt to evolving needs while maintaining cleanliness standards.

Process Optimization: By reducing the presence of contaminants, ISO 9 cleanrooms contribute to improved process efficiency, lower rejection rates, and enhanced product quality.

Customization Options: ISO 9 cleanrooms can be customized to meet specific industry requirements, allowing for tailored solutions that address unique operational needs.

Conclusion

ISO 9 cleanrooms provide controlled environments that strike a balance between moderate cleanliness requirements and operational flexibility. By adhering to specific ISO standards, these cleanrooms contribute to contamination control, process optimization, and regulatory compliance across various industries. Understanding the characteristics, applications, design considerations, and maintenance requirements of ISO 9 cleanrooms is essential for industries seeking to achieve controlled and reliable manufacturing or research environments.

FAQs

Can an ISO 9 cleanroom be upgraded to a higher ISO class?

Yes, if the cleanliness requirements of a facility change over time, it is possible to upgrade an ISO 9 cleanroom to a higher ISO class by implementing appropriate design modifications and meeting the stricter cleanliness standards.

Are ISO 9 cleanrooms suitable for industries with stringent cleanliness requirements?

ISO 9 cleanrooms are generally better suited for industries with moderate cleanliness requirements. Industries with higher cleanliness requirements may opt for ISO 7 or ISO 8 cleanrooms to ensure compliance with more stringent standards.

Do ISO 9 cleanrooms require continuous environmental monitoring?

Yes, continuous environmental monitoring is recommended in ISO 9 cleanrooms to ensure that temperature, humidity, and particle counts are within the specified limits and to promptly address any deviations.

Can ISO 9 cleanrooms be customized for specific industry requirements?

Yes, ISO 9 cleanrooms can be customized to meet specific industry requirements, such as integrating specialized equipment, implementing additional controls, or accommodating unique process needs.

Is ISO certification necessary for ISO 9 cleanrooms?

ISO certification is not mandatory for ISO 9 cleanrooms. However, compliance with ISO standards and periodic audits by accredited organizations are recommended to ensure adherence to the specified cleanliness and environmental control requirements.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Laminar Flow Clean Room, Clean Room Production, ISO Room, 100000 Level Purification Workshop, ISO 4 Cleanroom, Clean Room Level, Cleanroom ISO 6.