100000 Level Purification Workshop: Achieving the Pinnacle of Cleanliness

- 2024-01-22

- View 10

In industries where precision, quality, and safety are paramount, such as microelectronics, pharmaceuticals, and aerospace, maintaining an ultra-clean environment is crucial. One of the highest levels of cleanroom classification is the 100000 level purification workshop often referred to as a Class 8 cleanroom In this article, we will explore what a 100000 level purification workshop entails, its significance, and its applications in industries that demand the utmost cleanliness and purity.

1. Understanding Cleanroom Classification

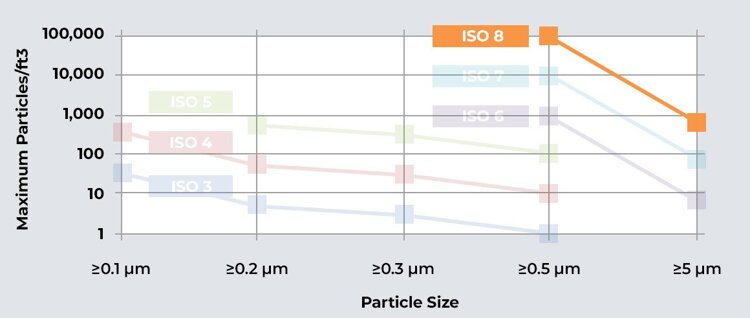

Cleanrooms are classified based on the maximum allowable concentration of airborne particles per cubic meter of air. The classification system, outlined in the ISO 14644-1 standard, ranges from ISO Class 1 (the cleanest) to ISO Class 9 (the least clean). Each class has specific requirements for particle counts and air cleanliness to meet the desired level of environmental control.

2. What is a 100000 Level Purification Workshop?

A 100000 level purification workshop, or a Class 8 cleanroom, is designed to meet the requirements of ISO Class 8 cleanroom classification. It signifies an environment with strict controls on particle contamination, allowing a maximum of 100,000 particles (≥0.5 micrometers) per cubic foot of air. This level of purification ensures a significantly cleaner environment compared to lower-level cleanrooms.

3. The Importance of a 100000 Level Purification Workshop

A 100000 level purification workshop is vital for industries where even the tiniest particles can compromise product quality, performance, and safety. Here are some key reasons why this level of cleanliness is essential:

Product Integrity: In industries like microelectronics and pharmaceuticals, where small particles can impact device functionality or contaminate sensitive drugs, maintaining product integrity is critical. A Class 8 cleanroom minimizes the risk of particle-induced defects and ensures consistent quality.

Worker Safety: Certain industries, such as pharmaceutical manufacturing, require a controlled environment to protect workers from exposure to airborne contaminants or hazardous substances. A 100000 level purification workshop provides a safe working environment by reducing the presence of potentially harmful particles.

Regulatory Compliance: Many industries operate under stringent regulations and standards to ensure quality, safety, and environmental protection. By operating in a Class 8 cleanroom, companies can meet these regulatory requirements and demonstrate their commitment to maintaining high standards of cleanliness.

4. Key Design Considerations

Designing a 100000 level purification workshop requires careful planning and attention to detail. Some crucial considerations include:

Air Filtration System: The air filtration system is a vital component of a Class 8 cleanroom. High-efficiency particulate air (HEPA) filters are used to remove airborne particles effectively and maintain the required cleanliness level.

Airflow Control: Proper airflow patterns, such as laminar flow, help minimize particle dispersion and ensure consistent air distribution throughout the cleanroom. This control aids in reducing particle accumulation on surfaces.

Seamless Surfaces: Smooth and non-porous surfaces in a cleanroom prevent particle accumulation and facilitate easy cleaning and decontamination.

Controlled Access: Implementing strict protocols for personnel entry and exit minimizes the introduction of contaminants. This includes the use of air showers, gowning rooms, and comprehensive training on cleanroom behavior.

5. Applications of a 100000 Level Purification Workshop

A 100000 level purification workshop finds applications in various industries that demand high levels of cleanliness. Some notable examples include:

Microelectronics: Manufacturing processes for semiconductors, microchips, and other electronic components require an environment free from particles that could compromise device functionality.

Pharmaceuticals: The production of pharmaceutical drugs necessitates a controlled environment to prevent contamination and ensure product safety and efficacy.

Biotechnology: Research and development laboratories working with sensitive biological materials benefit from a Class 8 cleanroom, as it minimizes the risk of contamination and preserves sample integrity.

Aerospace: The aerospace industry requires cleanrooms for manufacturing and assembling precision instruments, satellites, and spacecraft, where even small particle contamination can have severe consequences.

6. Maintaining Cleanliness in a 100000 Level Purification Workshop

To ensure the ongoing effectiveness of a 100000 level purification workshop, the following practices should be followed:

Regular Cleaning and Disinfection: Implementing a thorough cleaning and disinfection regimen helps maintain the cleanliness of surfaces, equipment, and tools within the cleanroom.

Routine Maintenance: Regular inspections of the air filtration system, monitoring of airflow patterns, and calibration of monitoring equipment are essential to uphold the desired cleanliness level.

Personnel Training: Proper training on cleanroom protocols and behavior is crucial to prevent the introduction of contaminants. This includes appropriate gowning procedures, aseptic techniques, and adherence to cleanroom etiquette.

Environmental Monitoring: Continuous monitoring of airborne particles, temperature, humidity, and other relevant parameters ensures that the cleanroom environment remains within the specified limits.

7. Conclusion

A 100000 level purification workshop plays a pivotal role in industries where cleanliness and precision are paramount. By meeting the requirements of ISO Class 8 cleanroom classification, these controlled environments provide the necessary safeguards to ensure product integrity, worker safety, and regulatory compliance. Through meticulous design, adherence to best practices, and proper maintenance, a 100000 level purification workshop serves as the pinnacle of cleanliness, enabling industries to achieve their goals of producing high-quality and safe products.

FAQs

Q1: Can a 100000 level purification workshop be upgraded to a higher cleanroom classification?

A1: Yes, it is possible to upgrade a 100000 level purification workshop to a higher cleanroom classification by implementing additional measures, such as improved air filtration systems and stricter environmental controls. However, this process requires careful planning and adherence to regulatory guidelines.

Q2: What are the permissible particle sizes and concentrations in a Class 8 cleanroom?

A2: According to ISO 14644-1, a Class 8 cleanroom allows a maximum of 100,000 particles per cubic foot of air, with a particle size of ≥0.5 micrometers.

Q3: How often should a 100000 level purification workshop be recertified?

A3: Recertification frequency depends on industry-specific regulations and internal quality management systems. Generally, cleanrooms undergo recertification annually or as required by regulatory authorities.

Q4: Are there specific gowning requirements for a Class 8 cleanroom?

A4: Yes, personnel entering a Class 8 cleanroom must adhere to specific gowning procedures, including the use of appropriate garments, shoe covers, hairnets, and gloves. These measures help minimize the introduction of particles and contaminants.

Q5: Can a 100000 level purification workshop be used for sterile manufacturing?

A5: While a Class 8 cleanroom provides a controlled environment, sterile manufacturing typically requires higher cleanroom classifications such as Class 7 or Class 5, depending on the specific industry requirements and regulatory standards.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. ISO 4 Cleanroom, Dust-Free Clean Room, Clean Room Level, Hospital Operating Theater Room, Cosmetics Clean Room Engineering, Laboratory Clean Room, Operating Room Purification Engineering.