Dust-Free Rooms: Creating Clean Environments for Enhanced Precision and Safety

- 2024-05-07

- View 12

In various industries, maintaining clean and dust-free environments is crucial for ensuring the quality of products and processes. Dust particles can adversely affect sensitive equipment, compromise manufacturing processes, and pose health risks to personnel. In this article, we will explore the concept of dust-free rooms, their importance across different sectors, design considerations, and the numerous benefits they offer.

1. Understanding Dust and Its Impact

Dust is a common form of airborne particles composed of various materials, including dirt, pollen, skin cells, and pollutants. When present in manufacturing environments, it can cause equipment malfunction, product defects, and health hazards, underscoring the importance of dust-free solutions.

2. The Significance of Dust-Free Rooms

Dust-free rooms, also known as clean rooms or controlled environments, are specialized spaces designed to maintain extremely low levels of airborne particles. They provide a controlled atmosphere to minimize contamination risks and create ideal conditions for sensitive processes.

3. Industries That Require Dust-Free Environments

Numerous industries rely on dust-free rooms to safeguard their operations, including semiconductor manufacturing, pharmaceuticals, biotechnology, aerospace, and precision engineering.

4. Designing a Dust-Free Room

Designing an effective dust-free room involves careful planning and adherence to specific guidelines:

4.1 HVAC and Air Filtration Systems

The heating, ventilation, and air conditioning (HVAC) system must be equipped with high-efficiency air filters to continuously circulate purified air throughout the room.

4.2 Material Selection for Surfaces and Furnishings

Choosing smooth and non-porous materials for surfaces and furnishings minimizes particle retention and facilitates easy cleaning.

4.3 Sealing and Positive Pressure

Sealing all possible entry points and maintaining positive pressure inside the room prevent external contamination from entering.

4.4 Regular Monitoring and Maintenance

Regular monitoring of airborne particle levels and stringent maintenance protocols ensure the room's continued compliance with cleanliness standards.

5. Cleanroom Classification Standards

Cleanrooms are classified based on the maximum allowable particle count per cubic meter. Two common standards used are:

5.1 ISO 14644-1 Standard

The ISO standard defines cleanroom classifications ranging from ISO 1 (fewest particles) to ISO 9 (highest particle count).

5.2 Federal Standard 209E (FS 209E)

The FS 209E standard was the previous US standard, also defining cleanroom classifications, but has been superseded by ISO 14644-1.

6. Benefits of Dust-Free Rooms

6.1 Enhanced Product Quality

By reducing the risk of product contamination, dust-free rooms contribute to higher product quality and consistency.

6.2 Improved Equipment Reliability

Maintaining a dust-free environment ensures the longevity and reliability of sensitive equipment.

6.3 Ensured Safety and Hygiene

Cleanrooms protect personnel from exposure to hazardous substances and minimize the risk of workplace accidents.

6.4 Compliance with Industry Regulations

Industries with strict regulatory requirements can achieve compliance by implementing dust-free rooms in their manufacturing processes.

7. Applications of Dust-Free Rooms

7.1 Semiconductor and Electronics Manufacturing

Semiconductor fabrication requires pristine environments to avoid defects in microchips and ensure optimal performance.

7.2 Pharmaceutical and Biotechnology

In pharmaceutical research and manufacturing, dust-free rooms are essential to prevent cross-contamination and ensure sterile conditions.

7.3 Aerospace and Defense

Aerospace industries rely on clean rooms for assembling delicate components and satellite systems.

7.4 Healthcare Facilities

Operating rooms and isolation units in healthcare facilities must maintain dust-free environments to minimize infection risks.

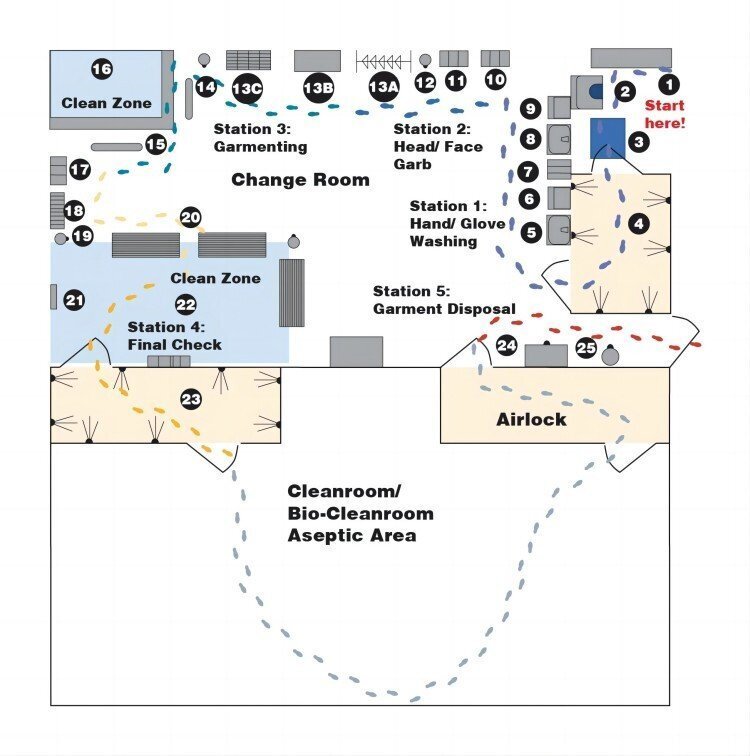

8. The Role of Personnel in Maintaining a Dust-Free Environment

Proper training and adherence to cleanroom protocols by personnel are crucial for sustaining a dust-free environment.

9. Future Trends in Dust-Free Room Technology

Advancements in air filtration, monitoring systems, and automation are driving the evolution of dust-free room technology.

10. Sustainable Practices in Dust-Free Room Design

Efforts to reduce energy consumption and waste generation in cleanrooms contribute to environmentally friendly practices.

11. Conclusion

Dust-free rooms play an integral role in industries that demand precision, safety, and quality. By employing advanced technology and adhering to strict standards, these controlled environments enable businesses to achieve optimal efficiency and meet stringent regulatory requirements.

FAQs

What is a dust-free room?

A dust-free room, also known as a clean room, is a controlled environment designed to maintain extremely low levels of airborne particles.

Which industries benefit from dust-free rooms?

Industries such as semiconductor manufacturing, pharmaceuticals, aerospace, and healthcare rely on dust-free rooms to ensure precision and safety.

What are the benefits of using a dust-free room?

Dust-free rooms enhance product quality, equipment reliability, safety, and compliance with industry regulations.

How are cleanrooms classified?

Cleanrooms are classified based on the maximum allowable particle count per cubic meter, with standards like ISO 14644-1 and FS 209E used for classification.

What role does personnel play in maintaining a dust-free environment?

Proper training and adherence to cleanroom protocols by personnel are essential for sustaining a dust-free environment.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Laminar Flow Clean Room, Clean Room Production, ISO Room, 100000 Level Purification Workshop, ISO 4 Cleanroom, Clean Room Level, Cleanroom ISO 6.