Understanding ISO 4 Clean Rooms: Purity Redefined

- 2024-01-19

- View 10

In the realm of advanced manufacturing, scientific research, and cutting-edge technology, maintaining an environment of utmost purity is of paramount importance. Enter the ISO 4 clean room a controlled space that sets the gold standard for minimizing contaminants and ensuring the highest levels of precision. In this article, we delve into the intricacies of ISO 4 clean rooms their significance, design considerations, and applications.

Introduction to ISO 4 Clean Rooms

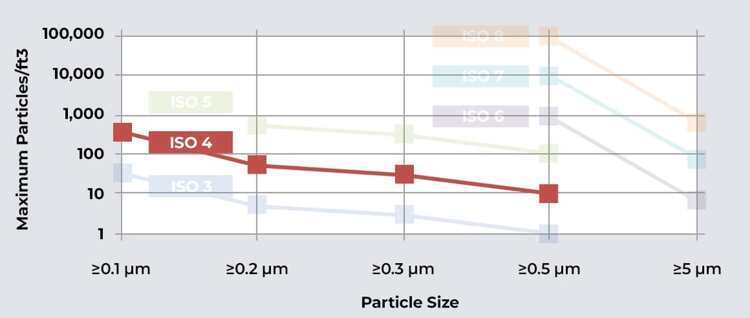

Clean rooms are classified based on their particulate count per cubic meter of air. The ISO classification system ranges from ISO 1 (the most stringent) to ISO 9 (the least stringent) ISO 4 clean rooms fall within the upper echelon of this system, boasting an incredibly low particle count and providing an environment suitable for the most sensitive and critical operations.

Stringent Purity Requirements

The defining characteristic of an ISO 4 clean room is its exceptionally low particle count. In this controlled environment the maximum allowable particle size is a mere 0.5 micrometers. This level of purity is achieved through a combination of meticulous design, advanced filtration systems, and stringent operational protocols.

Design and Construction

Creating an ISO 4 clean room requires meticulous attention to detail during the design and construction phases. The room must be built with materials that emit minimal particles and be free from potential sources of contamination. This often involves using smooth, non-porous surfaces, rounded corners, and specialized ceiling designs to prevent particle accumulation.

Air Filtration and Ventilation

At the heart of every ISO 4 clean room is a robust air filtration and ventilation system. High-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filters are employed to remove particles from the air, ensuring that the environment remains within the strict particle count limits. The controlled airflow patterns prevent the accumulation and dispersion of contaminants.

Applications of ISO 4 Clean Rooms

ISO 4 clean rooms find application in a diverse range of industries and fields:

Microelectronics Manufacturing: The production of semiconductors, microchips, and other intricate electronics demands an environment with minimal particle interference.

Pharmaceutical Research: In drug development, even the smallest contamination can lead to skewed results. ISO 4 clean rooms offer the purity required for accurate research.

Biotechnology: Activities such as cell culture and genetic research necessitate an environment free from external contaminants.

Aerospace Engineering: Precision in aerospace manufacturing is critical. ISO 4 clean rooms ensure that sensitive components remain untainted.

Medical Device Production: Devices like implants and surgical tools must be manufactured in a sterile environment to prevent complications.

ISO 4 Clean Room Conclusion

The ISO 4 clean room stands as a testament to human ingenuity in the pursuit of purity and precision. From enabling the creation of cutting-edge technologies to facilitating groundbreaking research, these controlled environments play a vital role in advancing various industries. Through meticulous design, stringent cleanliness protocols, and advanced air filtration systems, ISO 4 clean rooms pave the way for innovation that knows no bounds.

ISO 4 Clean Room FAQs

What is the main difference between ISO 4 and ISO 5 clean rooms?

ISO 4 clean rooms have stricter particle count limits compared to ISO 5 clean rooms, making them more suitable for highly sensitive operations.

Can ISO 4 clean rooms completely eliminate all particles?

While ISO 4 clean rooms significantly reduce particles, complete elimination is impossible due to factors like human presence and natural airborne particles.

Are ISO 4 clean rooms expensive to build and maintain?

Creating and maintaining ISO 4 clean rooms involves substantial costs due to specialized materials, advanced filtration systems, and stringent protocols.

What are the consequences of contamination in ISO 4 clean rooms?

Contamination in ISO 4 clean rooms can lead to compromised research, defective products, and potentially hazardous outcomes in various industries.

Are ISO 4 clean rooms regulated by industry standards?

Yes, ISO 4 clean rooms must adhere to specific standards outlined by international organizations like ISO and relevant industry regulatory bodies.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. ISO Class 8 Cleanroom, Cleanroom ISO Class Standards, Biopharmaceutical Cleanroom, Germfree Cleanroom, Cleanroom Packaging Services, Clean Room Installation, Dust-Free Clean Room Equipment.