Understanding Cleanroom ISO Class Standards

- 2024-01-11

- View 10

Cleanrooms play a vital role in industries where even the tiniest particles can have a significant impact on product quality and reliability. To ensure consistent cleanliness levels, the International Organization for Standardization (ISO) has established cleanroom classification standards. In this article, we'll delve into the details of cleanroom ISO class standards, their significance, and their applications.

Introduction

Cleanrooms are controlled environments designed to minimize airborne particles and contaminants. To maintain consistency in cleanliness, international standards have been established to classify cleanrooms based on the number of particles present in the air.

Importance of Cleanroom Classification

In industries such as electronics, pharmaceuticals, aerospace, and biotechnology, product quality and safety are paramount. Cleanroom classification ensures that the production and research processes occur within specific environmental conditions, reducing the risk of contamination.

Cleanroom ISO Class Standards

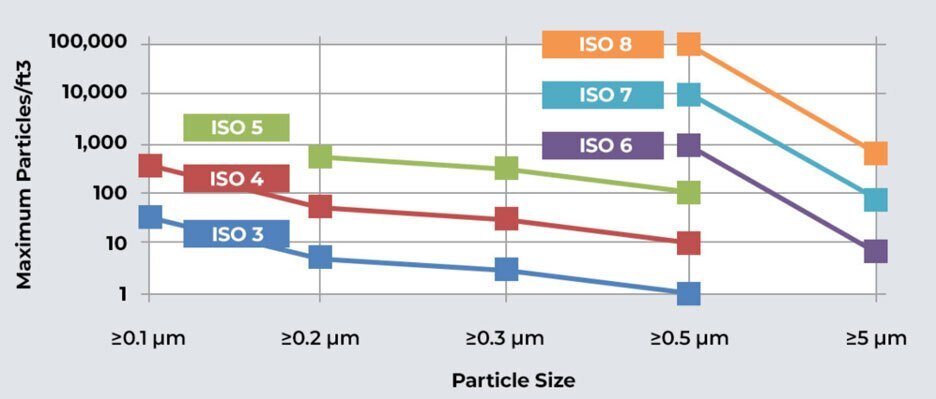

The ISO class standards define the maximum allowable particle count in a given volume of air. These standards are detailed in the ISO 14644-1 document, which outlines particle count limits for different cleanroom classes.

ISO 14644-1 Cleanroom Classification

ISO 14644-1 provides guidelines for cleanroom classification based on particle count in the air. The standard establishes various cleanroom classes, ranging from ISO Class 1 (fewest particles) to ISO Class 9 (most particles).

Understanding ISO Classes

ISO classes define particle count limits for particles equal to or larger than a specific size. For instance, an ISO Class 5 cleanroom restricts particles ≥0.5 micrometers per cubic meter of air, while an ISO Class 7 cleanroom permits particles ≥5 micrometers.

Factors Affecting Cleanroom Classification

Cleanroom classification is influenced by factors such as air filtration, airflow patterns, personnel movement, and equipment usage. These variables impact the concentration of particles within the environment.

Applications of Cleanroom ISO Class Standards

Cleanroom ISO class standards find applications in diverse industries:

Microelectronics and Semiconductor Manufacturing

Pharmaceutical Production

Biotechnology Research

Optics and Precision Manufacturing

Medical Device Assembly

Cleanroom Maintenance and Monitoring

Regular monitoring and maintenance are crucial to ensuring cleanroom compliance. Particle counts, temperature, humidity, and pressure differentials must be consistently monitored and controlled.

Benefits of Adhering to ISO Standards

Adhering to ISO cleanroom standards offers several benefits:

Enhanced Product Quality

Regulatory Compliance

Improved Yield and Efficiency

Reliable Research Results

Challenges in Maintaining Cleanroom Standards

Maintaining strict cleanliness levels presents challenges such as operational costs, training requirements, and maintaining equipment and facilities.

Future Trends in Cleanroom Technology

As technology evolves, cleanrooms are integrating advanced monitoring systems, robotics, and automation to enhance contamination control, improve efficiency, and reduce human error.

Cleanroom ISO Class Standards Conclusion

Cleanroom ISO class standards provide a systematic approach to maintaining controlled environments. They ensure that industries demanding high precision and minimal contamination can achieve consistent and reliable results.

Cleanroom ISO Class Standards FAQs

What is the purpose of cleanroom classification?

Cleanroom classification serves to define and maintain controlled environments that minimize airborne particles, ensuring product quality and safety.

How are ISO cleanroom standards determined?

ISO cleanroom standards are determined by ISO 14644-1, which outlines particle count limits for different cleanroom classes based on particle size.

What are the key factors affecting cleanroom classification?

Factors such as air filtration, airflow patterns, personnel movement, and equipment usage influence cleanroom classification.

What industries benefit most from adhering to ISO cleanroom standards?

Industries such as microelectronics, pharmaceuticals, biotechnology, optics, and medical devices benefit significantly from adhering to ISO cleanroom standards.

How does automation impact cleanroom technology's future?

Automation, including advanced monitoring systems and robotics, will play a crucial role in enhancing contamination control, improving efficiency, and reducing human error in cleanroom environments.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Biopharmaceutical Cleanroom, ISO Class 5 Cleanroom, ISO Class 6 Cleanroom, ISO Class 7 Cleanroom, Cleanroom Devices, Clean Room Solutions, Cleanroom Air Filtration System.