ISO Class 6 Cleanroom: A Closer Look at Controlled Environments

- 2024-01-08

- View 9

Cleanrooms are the backbone of industries that demand impeccable quality, such as electronics, pharmaceuticals, and aerospace. Among the various classification standards, the ISO Class 6 cleanroom stands out as a crucial space for maintaining precise and controlled conditions. In this article, we'll delve into the intricacies of an ISO Class 6 cleanroom discussing its significance, features, requirements, and benefits within the context of high-tech industries.

Introduction

Industries that deal with sensitive processes and products require environments free from even the tiniest contaminants Cleanrooms are meticulously engineered spaces where particle levels are controlled to prevent contamination. Among cleanroom classifications the ISO Class 6 cleanroom holds a pivotal role in providing an optimal environment for critical operations.

Understanding Cleanroom Classification

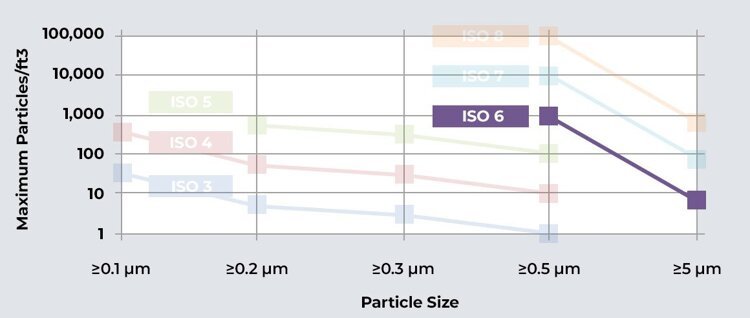

Cleanrooms are classified based on the number and size of airborne particles permitted per cubic meter of air. These classifications range from ISO Class 1 (the most stringent) to ISO Class 9 (less stringent). As the class number increases, the allowable particle count also rises.

ISO Class 6 Cleanroom: Unveiling the Significance

An ISO Class 6 cleanroom maintains a particle count of 3,520 particles per cubic meter at 0.5 micrometers. This level of cleanliness is essential in industries where even minimal particle contamination can lead to product defects, compromised research, or hazardous consequences.

Key Features of an ISO Class 6 Cleanroom

ISO Class 6 cleanrooms are designed with meticulous attention to detail. They feature advanced air filtration systems, controlled airflows, smooth and easy-to-clean surfaces, and tightly sealed construction to minimize particle infiltration. Regular monitoring and maintenance are essential to ensure compliance with the ISO 14644-1 standard.

Maintaining ISO Class 6: Stringent Requirements

Achieving and maintaining ISO Class 6 standards demand unwavering commitment. Strict protocols govern personnel attire, behavior, and movements within the cleanroom. All equipment and materials must undergo rigorous decontamination before entering the controlled space.

Benefits of ISO Class 6 Cleanrooms

The benefits of ISO Class 6 cleanrooms are multifaceted. They include improved product quality, reduced product defects, enhanced process reliability, compliance with regulatory standards, and minimized risk of contamination-related setbacks.

Applications and Industries

ISO Class 6 cleanrooms find applications across various sectors, including semiconductor manufacturing, pharmaceuticals, biotechnology, nanotechnology, and aerospace. These environments are essential for manufacturing microchips, conducting research, and assembling intricate medical devices.

Design and Layout Considerations

Designing an ISO Class 6 cleanroom demands expertise in architectural engineering, HVAC systems, and particle control. Proper ventilation, strategic placement of equipment, and ergonomic workflow design are critical for efficient and effective cleanroom operations.

Future Trends in Cleanroom Technology

As technology evolves, so do cleanroom practices. Advancements include more energy-efficient HVAC systems, smarter monitoring and control systems, enhanced automation, and the integration of Industry 4.0 principles for improved efficiency and quality.

ISO Class 6 Cleanroom Conclusion

ISO Class 6 cleanrooms serve as the backbone of industries that demand precision, quality, and reliability. By providing a controlled environment free from contaminants, these spaces ensure the integrity of products and processes, contributing to the success of high-tech sectors.

FAQs

What is an ISO Class 6 cleanroom?

An ISO Class 6 cleanroom is a controlled environment that maintains a specific particle count to prevent contamination in industries that require high levels of cleanliness.

What is the allowable particle count in an ISO Class 6 cleanroom?

An ISO Class 6 cleanroom permits a maximum of 3,520 particles per cubic meter at 0.5 micrometers.

What industries benefit from ISO Class 6 cleanrooms?

Industries such as electronics manufacturing, pharmaceuticals, biotechnology, nanotechnology, and aerospace benefit from ISO Class 6 cleanrooms.

What are the key features of an ISO Class 6 cleanroom?

ISO Class 6 cleanrooms feature advanced air filtration, controlled airflows, easy-to-clean surfaces, and strict protocols for personnel and equipment.

How does future technology impact cleanroom design?

Future cleanroom trends include energy-efficient systems, advanced monitoring and automation, and integration with Industry 4.0 principles.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Clean Room Solutions, Cleanroom Devices, Dust Free Clean Room Workshop, Class 100000 Clean Production Workshop, Laboratory purification engineering, Purification Workshop Manufacturer, Food Factory Clean Room.