Exploring the Benefits and Requirements of an ISO Class 7 Cleanroom

- 2024-01-09

- View 10

In the world of precision manufacturing, research, and technology, the concept of controlled environments is paramount. One such controlled environment is the ISO Class 7 Cleanroom a specialized space designed to meet stringent standards for cleanliness and contamination control. This article delves into the significance, features, and necessities of an ISO Class 7 Cleanroom shedding light on its applications across diverse industries.

1. Introduction

Cleanrooms play a pivotal role in industries where even minor contamination can lead to substantial repercussions. An ISO Class 7 Cleanroom is a controlled environment meticulously crafted to ensure a specific level of cleanliness, making it an indispensable asset in sectors ranging from pharmaceuticals to electronics.

2. Understanding ISO Class 7 Cleanrooms

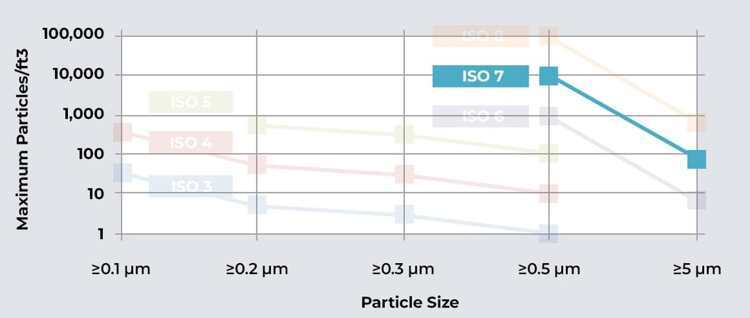

ISO Class 7 refers to a classification defined by the International Organization for Standardization (ISO) based on airborne particulate cleanliness Cleanrooms are classified from ISO Class 1 (the cleanest) to ISO Class 9 (the least clean). An ISO Class 7 Cleanroom permits a maximum of 352,000 particles per cubic meter that are 0.5 micrometers or larger in size.

2.1. Ventilation and Filtration

Cleanrooms of this class have advanced ventilation systems combined with high-efficiency particulate air (HEPA) filters. These filters play a crucial role in maintaining air quality by capturing particles with remarkable efficiency.

3. Key Features of an ISO Class 7 Cleanroom

Airflow Control: Airflow within an ISO Class 7 Cleanroom is carefully controlled to prevent the accumulation and spread of particles.

Positive Pressure: The room is typically maintained at a higher pressure than its surroundings to prevent unfiltered air from entering.

Sealed Surfaces: Surfaces are designed to be smooth and easy to clean, minimizing the potential for particle accumulation.

Regulated Clothing: Personnel within the cleanroom wear specialized garments to reduce the introduction of contaminants.

4. Necessities for Maintaining ISO Class 7 Standards

Maintaining the cleanliness of an ISO Class 7 Cleanroom requires:

Regular Monitoring: Continuous monitoring of particle counts and other environmental parameters.

Stringent Protocols: Adhering to strict protocols for personnel entry, gowning, and equipment usage.

Effective Training: Personnel need to be well-versed in cleanroom procedures and practices.

5. Applications of ISO Class 7 Cleanrooms

ISO Class 7 Cleanrooms find application in various industries:

Pharmaceuticals: Ensuring sterility in drug manufacturing and packaging.

Microelectronics: Preventing microscopic contaminants that could impact the functionality of electronic components.

Medical Device Manufacturing: Maintaining cleanliness during the production of intricate medical devices.

Biotechnology: Creating controlled environments for delicate research and experiments.

6. Advantages of ISO Class 7 Cleanrooms

Product Quality: Reduced risk of product contamination leads to higher quality outputs.

Regulatory Compliance: Cleanrooms facilitate adherence to strict industry regulations.

Enhanced Safety: Personnel are protected from exposure to potentially harmful substances.

Process Efficiency: Cleanrooms minimize the need for rework due to contamination-related issues.

7. Challenges and Considerations

Creating and maintaining an ISO Class 7 Cleanroom comes with challenges such as initial setup costs, ongoing maintenance expenses, and the need for meticulous procedures. However, the benefits often outweigh these challenges, especially in industries where precision is paramount.

8. Future Trends in Cleanroom Technology

The cleanroom industry is evolving with the integration of automation, data analytics, and advanced sensors. These innovations aim to further enhance cleanliness, efficiency, and monitoring capabilities.

9. Conclusion

An ISO Class 7 Cleanroom is an integral component of industries where cleanliness is a critical factor. Its ability to maintain strict standards for particulate cleanliness ensures product quality, safety, and regulatory compliance.

10. Frequently Asked Questions (FAQs)

1. How often are particle counts monitored in an ISO Class 7 Cleanroom?

Particle counts are usually monitored continuously or at regular intervals, depending on the specific requirements of the facility.

2. Can an ISO Class 7 Cleanroom be upgraded to a higher class?

Yes, with appropriate modifications and enhancements, it is possible to upgrade a cleanroom to a higher ISO class.

3. Are there specific gowning procedures for personnel entering an ISO Class 7 Cleanroom?

Yes, personnel need to adhere to strict gowning procedures to minimize the introduction of contaminants.

4. What role does air pressure play in an ISO Class 7 Cleanroom?

Maintaining positive air pressure prevents unfiltered air from infiltrating the cleanroom, helping to maintain cleanliness.

5. How are cleanroom standards determined by ISO?

Cleanroom standards are determined based on the permissible particle count and size within a cubic meter of air, as defined by the ISO classification.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Clean Room Solutions, Cleanroom Devices, Dust Free Clean Room Workshop, Class 100000 Clean Production Workshop, Laboratory purification engineering, Purification Workshop Manufacturer, Food Factory Clean Room.