ISO Class 5 Cleanroom: A Sanctuary of Precision and Purity

- 2024-01-09

- View 10

In the realm of controlled environments, the ISO Class 5 Cleanroom stands as a beacon of precision and purity. Designed to meet stringent cleanliness standards, this specialized space plays a crucial role in industries where even the tiniest particle can have significant consequences. This article dives into the significance, attributes, applications, and the meticulous requirements of an ISO Class 5 Cleanroom.

1. Introduction

Cleanrooms are sanctuaries of precision, essential for industries where contamination can lead to severe consequences. At the forefront of cleanroom classifications is the ISO Class 5 Cleanroom, meticulously designed to maintain ultra-low levels of airborne contamination.

2. Deciphering the ISO Class 5 Cleanroom

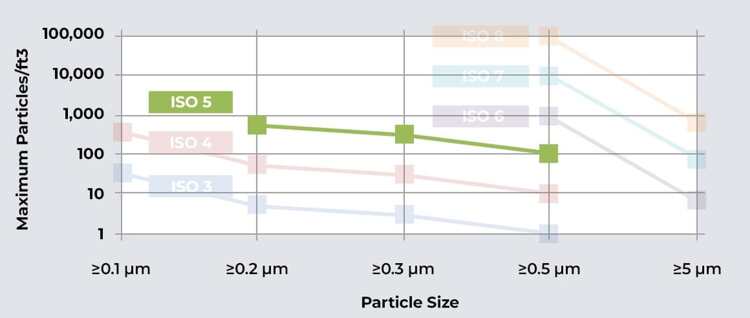

The International Organization for Standardization (ISO) classifies cleanrooms based on the number of airborne particles present in a given volume of air. An ISO Class 5 Cleanroom allows a maximum of 3,520 particles per cubic meter that are 0.5 micrometers or larger in size.

2.1. Airflow and Filtration

ISO Class 5 Cleanrooms incorporate advanced airflow patterns and filtration systems, often equipped with high-efficiency particulate air (HEPA) filters. These filters play a pivotal role in maintaining a pristine environment by capturing particles with exceptional efficiency.

3. Distinctive Features of ISO Class 5 Cleanrooms

Airflow Precision: The airflow within the cleanroom is meticulously controlled to minimize particle movement.

Positive Pressure: Maintaining positive air pressure prevents unfiltered air from infiltrating the cleanroom.

Smooth Surfaces: Surfaces are designed to be free of nooks and crannies, reducing the potential for particle accumulation.

Rigorous Protocols: Stringent protocols govern personnel gowning, entry, and equipment usage to minimize contamination.

4. Upholding Purity: Meeting ISO Class 5 Standards

Preserving the cleanliness of an ISO Class 5 Cleanroom involves:

Constant Monitoring: Continuous monitoring of particle counts and other environmental parameters.

Strict Procedures: Adhering to meticulous procedures for personnel entry, gowning, and equipment usage.

Thorough Training: Equipping personnel with comprehensive knowledge of cleanroom practices and protocols.

5. Versatile Applications Across Industries

ISO Class 5 Cleanrooms find applications in a spectrum of sectors:

Microelectronics: Crucial for maintaining particle-free conditions during semiconductor fabrication.

Pharmaceuticals: Ensures aseptic conditions during drug manufacturing.

Biotechnology: Provides a controlled environment for intricate research and experiments.

Medical Device Manufacturing: Safeguards cleanliness during the production of sensitive medical devices.

6. Benefits of ISO Class 5 Cleanrooms

Product Purity: Minimized contamination risk translates to enhanced product integrity.

Regulatory Compliance: Aids in adhering to strict industry regulations.

Personnel Protection: Safeguards workers from exposure to hazardous materials.

Operational Efficiency: Reduces the need for rework due to contamination-related issues.

7. Challenges and Considerations

Establishing and maintaining an ISO Class 5 Cleanroom comes with challenges, including initial setup costs, ongoing operational expenses, and the need for meticulous adherence to protocols. However, the benefits often outweigh these challenges, especially in industries where precision and purity are paramount.

8. Advancing Cleanroom Technology: A Glimpse into the Future

Cleanroom technology is on a constant evolution path, integrating automation, data analytics, and advanced sensors. These innovations aim to elevate cleanliness, efficiency, and monitoring capabilities.

9. Conclusion

The ISO Class 5 Cleanroom embodies the commitment to precision and purity in industries where even the slightest contamination is unacceptable. Its ability to uphold strict standards for airborne particle cleanliness contributes significantly to product quality, safety, and regulatory compliance.

10. Frequently Asked Questions (FAQs)

1. How often are particle counts monitored in an ISO Class 5 Cleanroom?

Particle counts are typically monitored continuously or at specified intervals, depending on the cleanroom's requirements.

2. Can an existing cleanroom be upgraded to meet ISO Class 5 standards?

Yes, with appropriate modifications and enhancements, existing cleanrooms can be upgraded to meet the criteria of an ISO Class 5 Cleanroom.

3. What are the gowning procedures for personnel entering an ISO Class 5 Cleanroom?

Personnel must follow strict gowning procedures, including specialized garments, to minimize the introduction of contaminants.

4. How does positive air pressure contribute to contamination control?

Maintaining positive air pressure prevents unfiltered air from infiltrating the cleanroom, enhancing overall purity.

5. How are cleanroom standards defined by ISO?

Cleanroom standards are defined based on the permissible particle count and size within a cubic meter of air, as outlined by the ISO classification.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Clean Room Solutions, Cleanroom Devices, Dust Free Clean Room Workshop, Class 100000 Clean Production Workshop, Laboratory purification engineering, Purification Workshop Manufacturer, Food Factory Clean Room.