Dust Free Clean Room Workshop Standards

- 2024-02-01

- View 11

Dust Free Clean Room Workshop is used for a wide range of applications Dust Free Clean Room Workshop is widely utilised in high-tech and modern scientific fields such as electronics, aerospace, bio-engineering pharmaceuticals, precision machinery, chemicals, food, machinery manufacturing.

Nowadays, many industries implement cleanroom purification projects, which remove (control) pollutants and dust from the air and create a clean and comfortable environment Cleanroom engineering is mainly reflected in laboratories, food workshops, operating theatres, electronics workshops, biopharmaceuticals and other areas.

The design of the dust free clean room workshop is mainly to ensure the cleanliness of the clean room or aseptic room, on the basis of the conditions of use and air conditioning, in consideration of doing the same and airflow status, in the structure of the clean room, to take into account the changing room, lounge, management room, cleaning room, these spaces are to achieve the effect of dust-free and sterile, and according to the airflow type, can be divided into vertical laminar flow type, horizontal laminar flow type, non-vertical laminar flow type. The specific use of what kind of cleanroom, and according to the clean room sterile room cleanliness level and some other conditions to determine, and can be based on the way of airflow and the number of air changes to change the cleanliness of the cleanroom, is generally based on the indoor is the content of the work and products. There is also the dynamic state of the personnel to change the cleanliness of the airflow.

However, depending on the occasion, a certain amount of exhaust air should be provided. In a cleanroom project the material used in the cleanroom must be free of gaps and cracks, and the surface must not be sticky, and there must be no wear and tear, no peeling of the surface, and moisture permeability, good attraction, thermal perfusion rate, and other materials are essential. The combination of good processing performance is indispensable. In terms of structure, the structure of the cleanroom should be tightly airtight, the accumulation of dust and dirt should be small, and the chirri should not be prone to vibration, and at the same time, it should not produce turbulence.

In the entrance of the clean room to set the air shower room, the wall is also installed transfer box, as well as to ensure positive pressure and can exhaust the safety air valve baffle, set the air shower room, is to reduce personnel into the clean room or aseptic room with the dust and dust, on personnel for people shower, improve the cleanliness, the installation of transfer box, is to reduce the goods into the clean room aseptic room when the dust brought. The dust in the clean room is mainly caused by the staff and the goods in the room. It is therefore important that the cleanroom equipment is given adequate attention. It is also important to manage the pressure balance in the clean room and the contamination of the walls.

A dust free clean room workshop is a specially designed room in which micro-particles, harmful air, bacteria and other pollutants are removed from the air within a certain space, and the indoor temperature, cleanliness, indoor pressure, airflow speed and airflow distribution, noise and vibration, lighting and static electricity are controlled within a certain demand range. A dust free clean room workshop is also called a clean plant, cleanroom or clean room. A dust free clean room workshop has the characteristics to maintain the originally set performance of cleanliness, temperature, humidity and pressure.

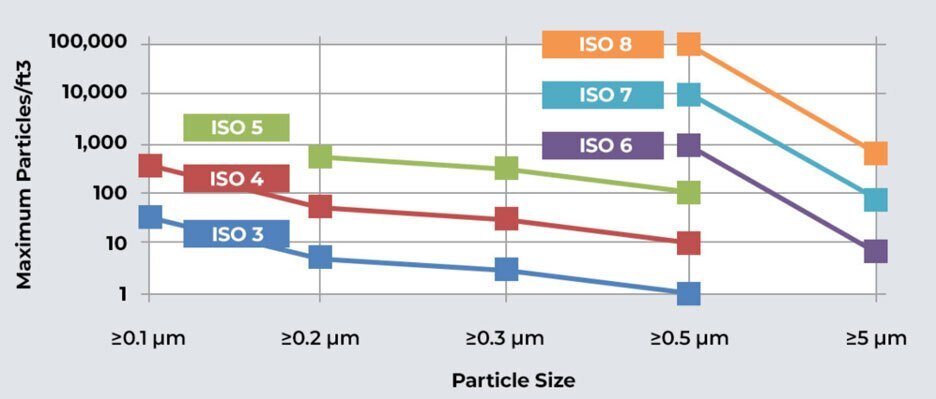

For many industries, there is a need to build a Dust Free Clean Room Workshop, but different industries, different products on the cleanroom clean level of demand is different, even if the same industry, in different production environments, different cleanroom production tasks are also different, the Dust Free Clean Room Workshop level of demand is also different. So we need to set the purification level according to the actual situation, such as production room, packaging room and laboratory cleanliness level is not the same, it is not possible to be all 100 level purification, also not all 10,000 level, 100,000 level purification, we need to consider both to meet the requirements of the purification level, but also to consider the cost requirements.

Class 1 cleanliness class: This level of cleanliness is mainly used in the microelectronics industry, and it is the industry with the highest requirements for cleanliness levels today. Because of the special nature of integrated circuits, even particles as small as 1 micron in diameter in the production room can affect the life of the product. Dust tends to make chips fail or become less stable, and when metal dust falls on an IC it can cause a short circuit. This is why integrated circuits are very sensitive to cleanliness levels and therefore clean air conditioning systems are vital for the microelectronics industry. In addition, the production of liquid crystals and optical fibres also requires a class 1 cleanliness level.

Class 10 cleanliness class:This class is mainly used in the semiconductor industry where the bandwidth is less than 2 microns. It is second only to class 1 in terms of air cleanliness and as our semiconductor technology is also developing, the requirements for cleanliness will be even higher in the future.

Class 100 cleanliness level:This is the most commonly used cleanliness level and has clear requirements for the concentration of bacteria in the air in addition to the number of dust in the air. This class is mainly used in the pharmaceutical industry for aseptic manufacturing.

Class 1,000 cleanliness level: Generally only the concentration of dust is required. It is mainly used for the high-quality production of optics, micro-axes, testing and assembly of gyroscopes for aircraft, etc.

Class 10,000 cleanliness level: Generally used for the production of hydraulic or pneumatic equipment and, in some cases, for the production of food and beverages.

Class 100,000 cleanliness level:This class can be used for many less demanding purification projects and can be used in many industrial sectors of production, food and beverage, parts assembly often use this class of purification.

One million cleanliness level: This level is the lowest, which means that the number of dust particles with a diameter greater than or equal to 0.5um per cubic metre of air is less than one million, and can be used in many industries where the requirements for cleanliness are not very high. It can be used in many industries that do not require a high level of cleanliness, such as printing plants, packaging plants, etc.

More of your interest