Which Cleanroom Classification Do I Need

- 2024-01-06

- View 16

If you clicked on this blog post, chances are you’re trying to decide which cleanroom classification is right for your business.

Or, maybe you’re not sure exactly what ISO cleanroom classification is.

Either way, you’re in luck. In this post, we’ll be talking about what ISO classification is, why it’s important, what factors should drive your decision making process, and explain how you can improve your cleanroom class at a later date.

The information in this blog will apply to all industries, including semiconductor manufacturing, pharmaceutical, or even automobile production. However, most of the examples we’ll reference in this post will be based on the pharmaceutical industry, so please keep that in mind.

Ready to learn more about cleanroom ISO classifications? Keep reading.

Why is ISO Classification Important?

If this is your first time diving into the world of cleanroom classification, the idea of ISO classes may be a bit confusing. So, before we get started, let’s go over some fundamentals.

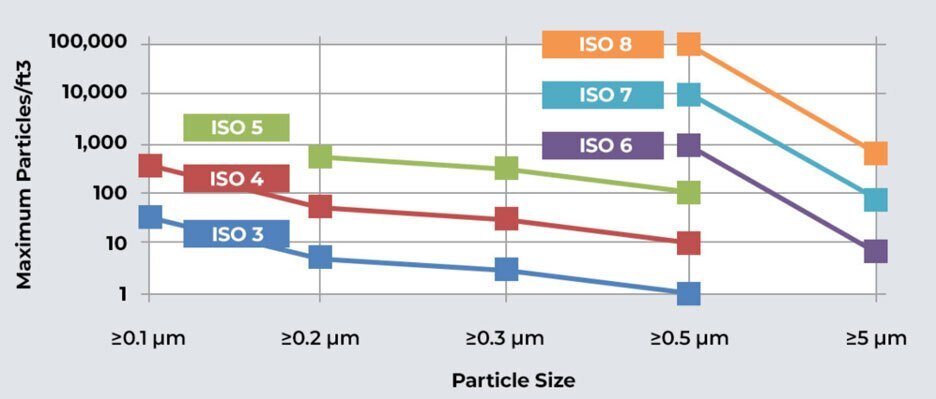

In the simplest terms, ISO classifications are ranges of acceptable particulate. Based on what’s needed for your process, different classifications of cleanrooms will be necessary. The higher the number, the more particulates you’ll find in the room. So ISO 5 cleanrooms will have less particulate and contamination than an ISO 8 cleanroom.Now that we’ve got the basics down, let’s look at the factors that will impact what ISO class of cleanroom your process will dictate.

1. Industry

The first and most important factor that will always dictate the class of cleanroom your business needs is the industry you operate in. You should consider that every industry has different requirements for particulates, finishes, and cleaning, and it’s up to you to gather this information.

What’s interesting is that although some industries have federally regulated standards, most do not. One big industry we see with FDA regulations is the pharmaceutical industry. Some of these regulations include USP, 797 & 800, and 503B.

Before deciding on the classification of cleanroom you want to install, look at your competitors who have more experience in this realm. By doing this, you’ll save yourself time, money, and potentially hours of research.

2. Competition

Like we mentioned previously, you can learn a lot from your competition. Not only will it help you stay legally compliant, it’ll also help you bring in new business. Now we’ve got your attention.How can having a lower ISO cleanroom, or any cleanroom for that matter, help you compete? Let’s look at an example.

Say you just bought a new business that creates decals for automobiles. You’ve been invited to bid for a project that could be a huge source of revenue for your company. Your two biggest competitors have an ISO 8 cleanroom, and an ISO 7 cleanroom You don’t have a cleanroom, but your product turns out great..most of the time.

The bid will more than likely go to the company with an ISO 7 cleanroom. This is because of one very important factor: higher predicted outcome of quality. A higher predicted outcome of quality means that you’re more trustworthy, cost-efficient, and easier to work with, regardless of what your sales rep says.

Simply put, having a cleanroom with a class on par with your competitors helps you stay current and put your best foot forward when bidding for jobs.

3. Internal Quality Control

Last but certainly not least is internal quality control. A lot of people miss just how important this is. By doing the legwork up front to build a cleanroom for quality control, you’re saving your business a large amount of money each year by eliminating product waste.

Not only that, but you’re also setting a standard for yourself that your customers and competitors will notice. By establishing guidelines for product quality, customers will trust what you produce that much more.

How can I determine which class of cleanroom establishes a high level of quality control for my business? That’s where we come in. Kwang Cleanroom has worked on cleanrooms across a variety of industries, and have developed a specific process for helping you decide on an ISO classification that’s right for you.

First, we have a conversation about the type of issue that’s occurring in the process, and how much particulate is entering the room. Next, we’ll run an analysis of the room to see what and where the issue really is. Finally, we’ll make suggestions based on what we’ve seen, and make the adjustments necessary to your cleanroom process.

Setting a level of quality control can be difficult due to self-policing, but it is absolutely crucial to the health of your business.

.jpg)

Don’t let cleanroom ISO classifications intimidate you. By using these three sections as a guide, you can be well on your way constructing the perfect cleanroom for your process. As always, our team of cleanroom experts are ready to assist you if you have any questions.

Kwang Cleanroom is proud to offer examples of a variety of our cleanroom projects below. Aseptic Purification Cleanroom Of Food Factory, Electronic Dust Free Cleanroom, GMP Cleanroom For Medical Devices, Dust Free Cleanroom Of Printing Industry, Blow Molding Film Purification Cleanroom, Aseptic inoculation Cleanroom For Edible Bacteria, Purification Projects In Other Industries.